The inner tube is one of the crucial components of a bicycle, available in various materials, each with unique characteristics. Manufacturers use different materials to manufacture different types and grades of inner tubes to meet various riding needs and conditions. Common bike inner tube materials include BUTYL, LATEX, and TPU. Different Bike inner tube materials, BUTYL vs LATEX vs TPU, exhibit differences in performance, durability, and cost, allowing riders to choose the suitable material based on their specific requirements. While tubeless tires are increasingly popular in road, gravel, and mountain biking, the majority of bicycles worldwide still use inner tubes. We have seen bicycles equipped with inner tube tire systems win many important world-class races, indicating that inner tube technology remains worthy of further exploration and research according to SUMLON.

1)BUTYL

Inner tubes made of BUTYL are typically black and are the most common bike inner tube material currently available. BUTYL inner tubes exhibit excellent air retention properties, effectively maintaining air pressure and reducing the frequency of punctures, thus eliminating the need for frequent inflation by riders. This feature is particularly advantageous for daily commuting and long-distance rides, as it reduces maintenance requirements, making cycling more convenient and reliable. BUTYL inner tubes also offer good durability. Their material properties provide a certain level of puncture resistance when encountering sharp objects, although not as much as some high-end bike inner tube materials like thermoplastic polyurethane (TPU). However, compared to Latex, BUTYL demonstrates stronger resistance to punctures and abrasion. This makes BUTYL inner tubes perform exceptionally well on general urban roads and relatively flat riding surfaces.

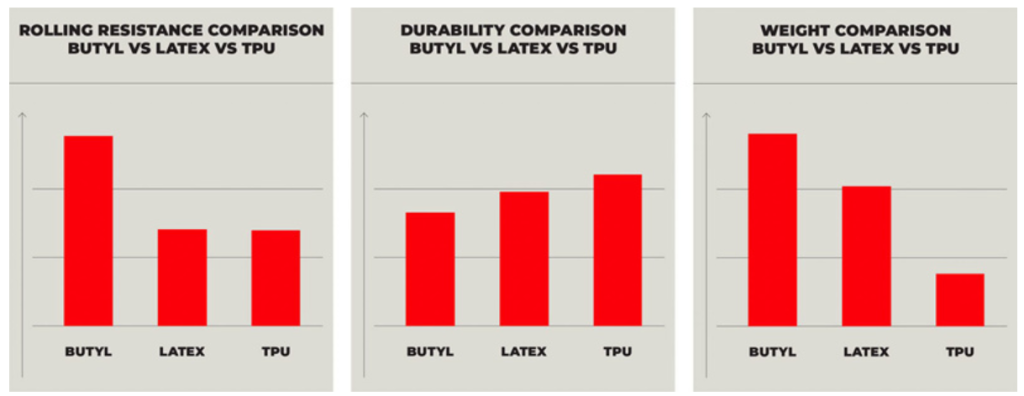

BUTYL inner tubes exhibit mediocre performance in terms of rolling resistance. According to relevant tests, BUTYL inner tubes tend to have higher rolling resistance, meaning more effort is required while cycling, which could potentially impact cycling efficiency and speed. However, for riders whose primary focus isn’t on racing, this drawback may not be significant. BUTYL inner tubes also have relatively higher weight, which could be a factor to consider for competitive athletes or long-distance riders who prioritize lightweight equipment. The added weight increases the overall burden on the bicycle, affecting climbing and acceleration performance.

Overall, it boasts excellent air retention properties, able to maintain pressure for extended periods without leakage, making it highly popular for both daily and long-distance riding. BUTYL inner tubes are relatively low-cost and offer good durability, suitable for most leisure riders and regular commuters.

2)LATEX

Inner tubes made of LATEX are typically light-colored. Rubber inner tubes exhibit lower rolling resistance, significantly enhancing cycling efficiency, making them particularly suitable for racing and long-distance riding. They also offer a degree of flexibility, providing better riding comfort and grip. Despite LATEX’s advantage in rolling resistance, its durability is inferior to other materials, making it prone to punctures or wear and requiring frequent replacement or repair. The weight of LATEX falls between BUTYL and TPU, making it not the lightest option available.

Overall, LATEX is renowned for its exceptional elasticity and flexibility, providing superior riding comfort and grip. Due to its material characteristics, LATEX performs excellently in absorbing vibrations and impacts, making it highly suitable for off-road cycling and competitive use. However, LATEX inner tubes come at a higher price and require more maintenance, needing regular checks and adjustments of air pressure.

3)TPU

Inner tubes made of TPU are typically transparent or translucent, and they often come in bright colors. TPU inner tubes excel in durability, boasting high resistance to punctures and abrasion, making them highly suitable for use in demanding environments. They are the lightest in weight, contributing to overall bike weight reduction, enhancing agility and speed while riding. Despite TPU’s significant advantages in durability and weight, it also exhibits low rolling resistance, meaning less effort is required while cycling.

However, TPU comes at a higher cost, which may not be suitable for budget-conscious cyclists. Generally, BUTYL inner tubes start at $8, LATEX inner tubes at $16, while TPU inner tubes start at $35. Many people consider spending twice the money for marginal benefits not cost-effective. However, SUMLON believes that compared to expensive ceramic bearings and carbon fiber bike parts, $70-80 for a pair of TPU inner tubes is not unreasonable. Upgrading to a pair of TPU inner tubes is a good choice to improve overall bike performance at a reasonable cost. In cycling, power is never free. Spending $70 can reduce the rotating weight and rolling resistance of the wheelset and increase durability. Additionally, the replaced BUTYL inner tubes can serve as spare tubes. In China, a pair of TPU inner tubes can even be priced below $20.

Additionally, TPU inner tubes are not as heat-resistant as LATEX inner tubes. For every increase of 3°C in temperature, the tire pressure may increase by approximately 1%. If inflated in a cool indoor environment but ridden in hot summer conditions, the tire pressure could increase by around 8 psi. When installing TPU inner tubes on rim brake wheelsets, extra caution should be taken to control brake heat, especially when descending long slopes.

Summary : BUTYL vs LATEX vs TPU

TPU material is a relatively new inner tube material, known for its high puncture resistance and durability. TPU inner tubes require minimal inflation and are suitable for use in demanding environments and long rides. However, the material comes at a higher cost and weight, primarily used in specific professional fields such as extreme sports and long-distance travel. The three types of inner tubes using different materials also differ in the difficulty of repair. Repair patches for BUTYL inner tubes are the most common, while the elasticity of inner tubes made from the other two materials is greater, making repairs slightly more challenging.

Suggestion on Bike Inner Tube Materials: BUTYL vs LATEX vs TPU

BUTYL vs LATEX vs TPU, urban commuters may prefer BUTYL inner tubes for stable performance and lower maintenance costs, while mountain bikers or competitive riders may lean towards LATEX inner tubes for higher comfort and grip. Professional extreme athletes may opt for TPU inner tubes to ensure stable performance and reliability even in the most demanding conditions.

By the way, SUMLON has been manufacturing bicycle parts for over 15 years. Contact us if you are looking for a bike parts factory or a one-stop wholesaler. Peace