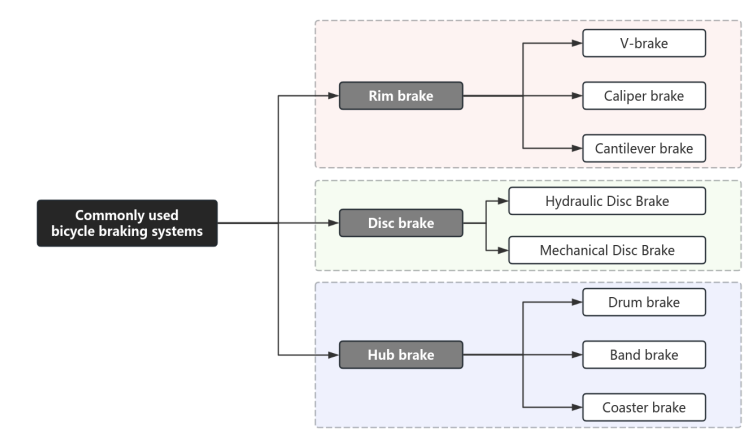

In this article, I’m going to introduce you to the bike brake types that are still popular today, how they work, and their pros and cons. We’ll look at the main bike brake types like rim brakes, disc brakes, and hub brakes, and dive into specific types like V-brakes, caliper brakes, cantilever brakes, drum brakes, band brakes, and coaster brakes. There are definitely more bicycle brake types out there, but for now, we’ll focus on these common ones. Later on, I’ll write another piece about how bicycle brake systems have evolved over time, where we’ll try to cover all the different types that have come and gone throughout history. So just to recap, this article is all about the brake systems you see on bikes today, and I hope it helps you get a good understanding of the basics!

1.Rim brake – old school bicycle brake types

Rim brakes include the V-brake, caliper brake, and cantilever brake. Those are all common bicycle brake types. When you pull the brake lever, the rim brake system creates friction by pressing the brake pads against the rim, which slows down or stops the bicycle. All types of rim brakes operate on the same principle. Their differences lie solely in the various mechanical designs that achieve the goal of “pressing the brake pads against the rim by pulling the brake cable.” I believe that after looking at the product images below, you’ll easily understand how they differ.

1.1 V-brake

How V-Brakes Work

V-brakes, also called direct-pull or linear-pull brakes, operate by pulling the brake cable, which in turn moves the arms of the V-brake together. These arms are positioned on either side of the wheel. When the arms come together, the brake pads at their ends press against the wheel rim. This contact creates friction, effectively slowing down or stopping the bike. As one of the old school bicycle brake types,V-brake is still widely used nowadays.

Pros and Cons of V-Brakes

V-brakes are known for their strong and reliable braking power, making them suitable for various riding conditions. They are lighter than some other brake systems, like disc brakes, and are generally more affordable to buy and maintain. The straightforward design of V-brakes makes installation, adjustment, and maintenance relatively simple. Plus, they are compatible with a wide range of bicycles.

However, using V-brakes gradually wears down the wheel rims, eventually requiring rim or wheel replacement. They can also lose effectiveness in wet or muddy conditions since water and debris reduce the friction between the pads and the rim. Long or steep descents can lead to heat buildup, which might decrease braking performance or damage the rim. V-brakes need enough clearance between the brake arms and the tire, which can be an issue with wider tires or mudguards. Additionally, proper pad alignment is crucial for optimal performance; misaligned pads can cause uneven wear and reduce braking efficiency.

1.2 Caliper brake

How Caliper Brakes Work

As one of the oldest bicycle brake types. Caliper brakes operate by using a brake cable to pull the calipers together. These calipers are usually above the wheel and are single-connected with the pivot point. When you pull the brake lever, the cable tightens, causing the calipers to squeeze together. This action presses the brake pads against the sides of the wheel rim, creating friction that slows down or stops the bicycle.

Pros and Cons of Caliper Brakes

Caliper brakes are famous for their simplicity and reliability. They are lightweight and relatively easy to install and maintain. Additionally, caliper brakes are commonly on road bikes, making them widely available and compatible with many standard bicycle designs. Their straightforward mechanism means fewer parts that can fail, contributing to their reliability.

But caliper brakes have some limitations. Like V-brakes, they can wear down the wheel rims over time, necessitating eventual rim or wheel replacement. Their performance can diminish in wet or muddy conditions, as water and debris can interfere with the friction needed for effective braking. They also require adequate clearance between the brake arms and the tire, which might be an issue with wider tires or certain frame designs. Additionally, caliper brakes may not provide as much stopping power as other systems like disc brakes, especially on long or steep descents where heat buildup can reduce their effectiveness. Proper pad alignment is essential to avoid uneven wear and maintain braking efficiency.

1.3 Cantilever brake

How Cantilever Brakes Work

Cantilever brakes function by using a brake cable to pull two arms, each mounted on opposite sides of the wheel, towards the rim. The cable runs through a yoke that splits into two shorter cables, each attached to a brake arm. When you pull the brake lever, the main cable tightens, causing the arms to pivot around their mounting points and the brake pads to press against the wheel rim. This contact creates friction, which slows down or stops the bicycle.

Pros and Cons of Cantilever Brakes

Cantilever brakes are famous for their strong braking power and versatility. They are particularly effective for bikes with wider tires, such as cyclo-cross and touring bikes, because they provide ample tire clearance. The design of cantilever brakes also makes them relatively easy to adjust and maintain, and they are generally more affordable than disc brakes. Additionally, their simple mechanism means there are fewer parts that can malfunction.

Cantilever brakes have some drawbacks. Like other rim brakes, they can wear down the wheel rims over time, necessitating eventual rim or wheel replacement. Their performance can be compromised in wet or muddy conditions, as water and debris can reduce the friction between the pads and the rim. While they offer good stopping power, they may not be as strong as disc brakes, especially under heavy loads or on steep descents. Proper alignment of the brake pads is crucial to ensure effective braking and prevent uneven wear. Finally, the setup of the yoke and cables can be more complex compared to V-brakes, potentially requiring more frequent adjustments.

2. Disc brake – new school bicycle brake types

Disc brakes include hydraulic disc brakes and mechanical disc brakes. The structure of mechanical disc brakes is relatively simple. It mainly consists of brake cables, brake levers, calipers and other components. When braking, the movement of the calipers is driven by pulling the brake cables, causing the brake pads to come into contact with the brake disc to generate friction and thereby achieve braking. While the structure of hydraulic disc brakes is more complex. It consists of brake levers, oil tubes, brake calipers and brake oil, etc. When you squeeze the brake lever, it will push the brake oil to flow in the oil tube, thereby transferring the pressure to the brake calipers and causing the brake pads to clamp the brake disc for braking.

2.1 Hydraulic disc brake

How Hydraulic disc Brakes Work

Hydraulic disc brakes use a fluid-filled system to transfer force from the brake lever to the brake caliper. When the rider pulls the brake lever, it pushes hydraulic fluid through a sealed hose towards the brake caliper. Inside the caliper, the fluid pressure pushes pistons, which in turn press the brake pads against a rotor mounted to the wheel hub. The friction between the brake pads and the rotor slows down or stops the bicycle.

Pros and Cons of Hydraulic Disc Brakes

Hydraulic disc brakes are renowned for their powerful and consistent braking performance. They provide excellent modulation, allowing riders to finely control the braking force. Unlike mechanical systems, hydraulic brakes are self-adjusting, meaning the pads automatically move closer to the rotor as they wear, ensuring consistent performance. They also perform well in all weather conditions, as the braking surface is away from the rim and less exposed to water and debris. Additionally, hydraulic systems often require less hand force to achieve strong braking, reducing fatigue on long rides.

However, hydraulic disc brakes come with some disadvantages. They are generally more expensive than other braking systems, both in terms of initial cost and maintenance. Servicing hydraulic brakes can be more complex and may require special tools and knowledge, making them less user-friendly for DIY repairs. Additionally, the hydraulic system can be susceptible to leaks or damage, which can compromise braking performance. They also add some weight to the bicycle, which might be a consideration for weight-conscious riders. Finally, while they offer strong braking power, the increased force can put more stress on the frame and fork, necessitating stronger and potentially heavier components. Hydraulic disc brake is definitely your best choice among all the bicycle brake types.

2.2 Mechanical disc brake

How Mechanical Disc Brakes Work

Mechanical disc brakes use a cable-actuated system to transfer force from the brake lever to the brake caliper. When the rider pulls the brake lever, it pulls a cable that runs through housing to the brake caliper. This cable movement activates a lever on the caliper, which pushes the brake pads against a rotor mounted to the wheel hub. The friction between the brake pads and the rotor slows down or stops the bicycle.

Pros and Cons of Mechanical Disc Brakes

Mechanical disc brakes are famous for their strong braking power and reliability. They provide better performance in wet and muddy conditions compared to rim brakes, as the rotor is located away from the rim and less exposed to debris. Mechanical systems are easier to adjust and maintain compared to hydraulic systems, as they do not require special tools or knowledge. Additionally, they are generally less expensive than hydraulic disc brakes, making them a more budget-friendly option for riders seeking disc brake performance.

However, mechanical disc brakes have some limitations. They require more frequent adjustments to maintain optimal performance, as cable stretch and pad wear can affect braking efficiency. Mechanical systems also require more hand force to achieve the same braking power as hydraulic systems, which can lead to hand fatigue on long rides. While they provide strong braking power, they may not offer the same level of modulation and fine control as hydraulic brakes. Mechanical disc brakes also add weight to the bicycle, and the increased braking force can put additional stress on the frame and fork, necessitating stronger components.

3. Hub brake – bicycle brake types that are not that popular now

A hub brake system on a bike is a way of braking where the force to stop is applied right to the hub of the wheel. There are a few common kinds of hub bicycle brakes. One is the coaster brake. You often see this on cruiser bikes and some kids’ bikes. With a coaster brake, when you pedal backward, it makes the brakes work. Another type is the drum brake. In a drum brake system, the shoes or pads push against the inside of a drum in the hub to make friction and slow the bike down or stop it.

Hub brakes have some good points. Compared to rim brakes, they’re usually not as bothered by weather like rain and mud. They also tend to be better protected from getting damaged and not as exposed to the outside. But, hub brakes might not stop the bike as well as some other types of brakes, like disc brakes. And they can be heavier and harder to adjust or fix sometimes.

3.1 Drum brake

How Drum Brakes Work

Drum brakes operate by using brake shoes inside a drum that is attached to the wheel hub. When the rider pulls the brake lever, it activates a linkage that forces the brake shoes outward against the inner surface of the drum. The friction between the brake shoes and the drum creates the braking force needed to slow down or stop the bicycle.

Pros and Cons of Drum Brakes

Drum brakes are known for their durability and low maintenance. Since the braking mechanism is enclosed within the hub, it is well-protected from dirt, water, and debris, making them highly reliable in all weather conditions. Drum brakes also require less frequent adjustments compared to other braking systems and generally have a long service life. Additionally, they provide consistent braking performance, regardless of environmental conditions.

Drum brakes have some disadvantages. They are typically heavier than other types of brakes, which can add weight to the bicycle. The enclosed design, while protective, can also make them more challenging to service and repair when necessary. Drum brakes tend to have less stopping power compared to disc brakes, which may be a concern for high-speed or heavy-duty cycling. Heat buildup can also be an issue during long or steep descents, potentially reducing braking performance. Furthermore, they may not offer the same level of modulation and precise control as other braking systems.

3.2 Band brake

How Band Brakes Work

Band brakes operate by using a flexible band that wraps around a drum or a cylindrical surface attached to the wheel hub. When the rider pulls the brake lever, it tightens the band around the drum. This action creates friction between the band and the drum, which slows down or stops the bicycle.

Pros and Cons of Band Brakes

Band brakes are appreciated for their simplicity and effective design. They are generally lightweight and can be easier to install and adjust compared to other braking systems. Band brakes provide a reliable braking performance in various conditions, and their enclosed design helps protect the braking mechanism from dirt and moisture.

However, band brakes have some limitations. They may not provide as much stopping power as disc or drum brakes, which can be a concern for heavier loads or high-speed riding. The braking performance can also diminish over time due to wear on the band or drum surface. Additionally, band brakes may require more frequent adjustments to maintain optimal performance, as the band can stretch and lose tension. They may also have a limited application on certain bike designs, making them less versatile than other braking systems. Lastly, the heat generated during braking can affect performance if not managed properly, especially on long descents.

3.3 Coaster brake

How Coaster Brakes Work

Coaster brakes, also known as backpedal brakes, work by engaging a braking mechanism located inside the rear hub of the bicycle. When the rider pedals backward, it activates a clutch mechanism that forces brake shoes against the inner surface of the hub. This contact creates friction, which slows down or stops the rear wheel, effectively bringing the bicycle to a halt.

Pros and Cons of Coaster Brakes

Coaster brakes are favored for their simplicity and ease of use. They provide intuitive braking, as the rider only needs to pedal backward to engage the brakes. This design eliminates the need for hand-operated brake levers, making them ideal for children and casual riders. Coaster brakes are also low maintenance, as the braking mechanism is enclosed within the hub, protecting it from dirt and debris.

However, coaster brakes have some limitations. They typically offer less braking power compared to other systems, which may be insufficient for steep descents or heavy loads. The design can also make it challenging to perform skid stops or emergency braking, as the brakes engage only when pedaling backward. Coaster brakes can be affected by wear and tear over time, which may require servicing or replacement of the internal mechanism. Additionally, they do not allow for the same level of control and modulation as hand-operated brakes, potentially leading to less precise stopping. Finally, if the brake mechanism fails, the rider may lose braking ability entirely, which can pose safety concerns.

By the way, SUMLON has been manufacturing bicycle parts for over 15 years. Contact us if you are looking for a bike parts factory or a one-stop wholesaler. Peace