Throughout the bicycle history, the quick release and thru-axle systems have each carved out their own distinct roles. The quick release system, which has been around for nearly a century, is renowned for its ease of use, allowing cyclists to quickly remove and reattach wheels, making transport and maintenance much more convenient. However, the thru-axle system, which emerged in the late 20th century, is more robust and durable, offering greater rigidity and stability, especially when dealing with high-intensity riding and rough terrain. At SUMLON, we believe that both systems contribute to the continuous advancement of bicycle technology, meeting the varied needs of different riders. Each system has its own unique set of advantages and disadvantages, so how should we choose between them? Here is a detailed explanation of “Quick Release vs. Thru-Axle,” covering what they are, how to use them, a comparison of their cost and performance, and more.

1. Quick Release System

1.1 What is a Quick Release?

A quick release is a device that allows for the rapid removal and installation of bicycle wheels. While primarily found on wheels, quick releases can also be seen on seat posts and other components. The system consists of a lever with an eccentric cam, a central rod, cam plates, conical springs, and a quick release nut. The quick release operates by using the cam’s eccentric design. Rotating the lever moves the cam, tightening or loosening the nut and allowing the wheel to be quickly secured or removed.

1.2 How to Remove and Install a Quick Release System

Removing and installing a quick release system is straightforward and usually tool-free. Start by opening the quick release lever, then rotate the lever to loosen the central rod. Once the rod disengages from the nut on the other side, you can pull the rod out from the hub and easily remove the wheel from the fork. To install, simply reverse the process.

1.3 Important Points for Quick Release Installation and Removal

(1) When removing the quick release, take care to keep track of small parts like washers and nuts, as they can easily be lost. One common criticism of the quick release system is the potential for losing these small components.

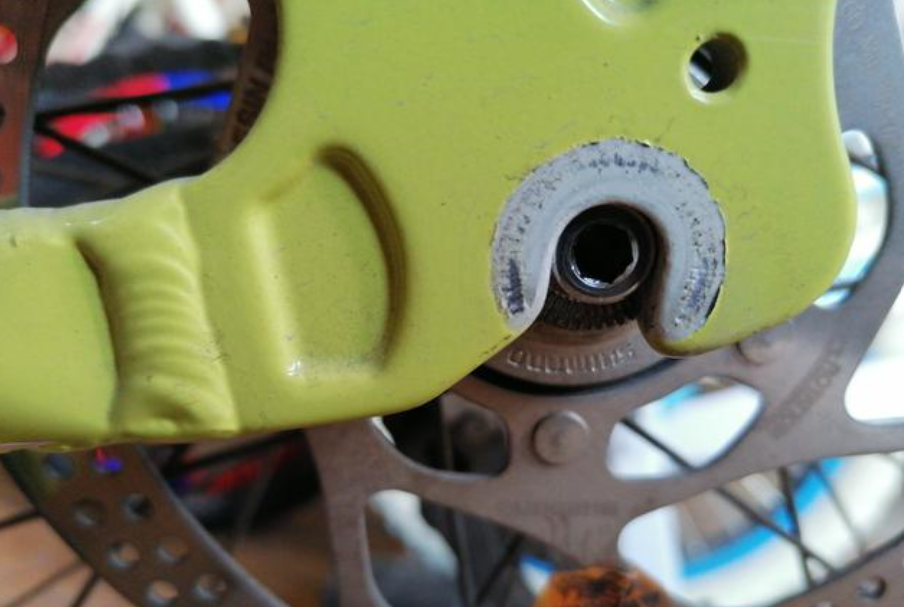

(2) Also, ensure that the quick release lever is parallel to the ground when the bike is upright; otherwise, the wheel might wobble. (3) Additionally, check that the quick release lever and cam plate are properly engaged, with the cam’s protrusion fitting snugly into the cam plate’s recess. Failure to do so could cause the quick release to loosen during a ride, potentially leading to accidents. (4) Lastly, ensure that the quick release lever does not contact the disc brake rotor. Ideally, the lever should be positioned perpendicular to the ground to avoid friction between the lever and rotor, which could cause noise, loosening, or system failure.

2. Thru-Axle System

2.1 What is a Thru-Axle?

A thru-axle is a more advanced wheel attachment system that offers greater strength and stability than traditional quick releases, making it well-suited to high-intensity riding. The system typically includes a solid metal axle, nuts for securing the axle to the frame at both ends, and washers that adjust spacing and protect the frame and wheel assembly. To install a thru-axle, insert the axle through the mounting holes in the frame and secure it by tightening the end nuts, creating a rigid and stable connection. This design reduces wheel wobble and deformation during intense activities like downhill or off-road riding, enhancing safety and control, though it is somewhat more complicated to install and remove.

2.2 How to Remove and Install a Thru-Axle System

To remove a thru-axle, first ensure that the bicycle is in a safe and stable position, and release the brake system if necessary. Use an appropriate tool, such as a wrench, to loosen the nuts at the axle ends. Slowly slide the axle out of the mounting holes, taking care not to damage the frame or other components. Keep the nuts and washers safe during this process. To install a thru-axle, insert the axle into the mounting holes in the frame, ensure it is fully inserted, then add the washers and tighten the nuts. Use a tool to achieve the proper level of tightness, ensuring the nuts are neither too loose, which would make the wheel unstable, nor too tight, which could damage components. After installation, check that the wheel spins smoothly and you have securely fastened the axle.

2.3 Important Points for Thru-Axle Installation and Removal

The process of replacing a thru-axle is generally simpler than with a quick release, with fewer parts to misplace and less chance of incorrect installation leading to wheel wobble. However, it’s crucial to ensure that the thru-axle you purchase has the correct length and diameter for your bike. When installing, make sure the nuts are tightened to the recommended torque, typically between 10-20 Nm. Unlike quick release systems, which can be removed by hand, removing a thru-axle requires a wrench. If you’re planning a long ride, carry a wrench that fits your thru-axle.

3. Can I Replace My Quick Release with a Thru-Axle?

In general, quick releases are more convenient to install and remove, and you don’t need to carry tools. They are also lighter than thru-axles. However, thru-axles offer better rigidity and stability. People often ask if they can replace their quick release system with a thru-axle. Unfortunately, in most cases, doing so requires replacing the fork, frame, and hubs as well.

Both systems serve to secure the hub to the fork or frame, which means they must be compatible with the mechanical structure of the hub and fork/frame. Quick release axles typically have a diameter of about 5 mm, while thru-axle diameters vary, with common mountain bike thru-axles being 15 mm or 20 mm, and road bike thru-axles often 12 mm. Hubs designed for quick releases have smaller axle holes. Therefore, if you buy a 15 mm thru-axle, it won’t fit into a hub designed for a quick release. Additionally, quick release-compatible forks and frames usually have U-shaped openings that match the quick release axle’s diameter. In contrast, thru-axle-compatible forks and frames have threaded holes for the axle to pass through, enhancing rigidity.

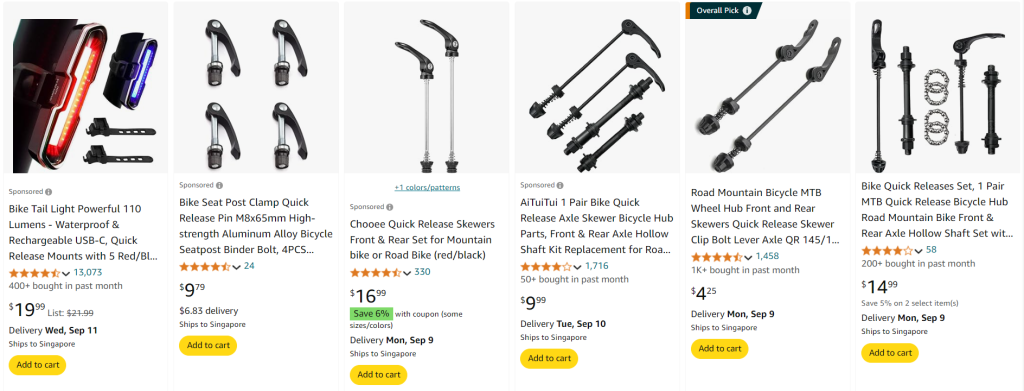

4. Thru-Axle vs. Quick Release : Price Comparison

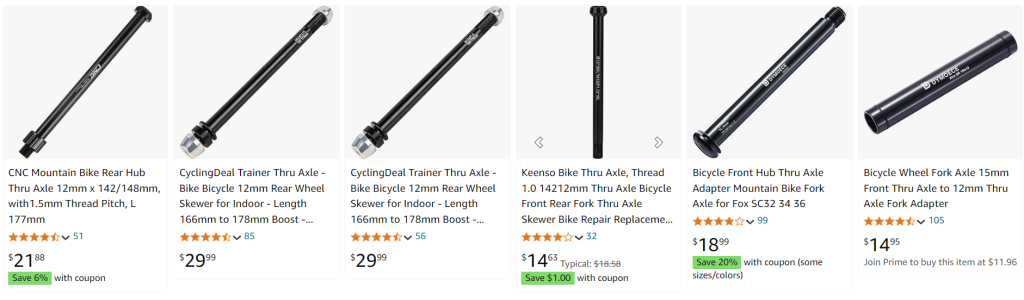

A quick search on Amazon will show that quick releases generally cost between $5 and $15, while thru-axles are typically priced at more than twice that, ranging from $15 to $30.

5. Thru-Axle vs. Quick Release : Performance Comparison

5.1 Thru-Axle vs. Quick Release : Structure and Fastening Mechanism

A quick release typically consists of a threaded rod, a lever, a nut, and two conical springs. The fork and rear stays using quick releases usually have a U-shaped design. The quick release works by rotating the lever, which tightens or loosens the nut, compressing or releasing the springs to secure or remove the wheel. Thru-axles, on the other hand, feature a thicker axle that must be rotated to install. The fork holes are closed rather than open, with a threaded center hole. By rotating the axle, it threads into the fork or frame, creating a more secure connection.

5.2 Thru-Axle vs. Quick Release : Safety

Quick releases provide sufficient clamping force under normal use but may loosen during high-intensity off-road riding or extreme maneuvers due to vibrations or impacts. In extreme cases, they might bend, break, or detach from the bike, posing a safety risk. For example, if the quick release loosens during high-speed riding or on rough terrain, the wheel could detach, leading to serious accidents. Problems can also arise if you did not install the quick release correctly or adequately tightened.

Thru-axles, with their larger diameter and robust structure, can withstand greater stress and impact, making them safer. In high-intensity environments like downhill racing or heavy off-road riding, thru-axles ensure that the wheels remain securely attached to the frame, significantly reducing the risk of wheel detachment. The closed design of the thru-axle also means the wheel is unlikely to loosen after installation, reducing the chances of issues like brake rub caused by wheel misalignment.

5.3 Thru-Axle vs. Quick Release : Rigidity and Handling Stability

Quick releases have relatively weak rigidity, which may cause some deformation under heavy pedaling or significant impact. This deformation can affect handling stability, making the connection between the wheel and frame feel less secure during high-speed riding or intense maneuvers, which can impact precision and responsiveness.

Thru-axles, with their robust structure and secure connection, provide greater rigidity. This ensures that the relative position between the wheel and frame or fork remains stable, even under heavy pedaling, high-speed cornering, hard braking, or riding on rough terrain. The increased rigidity allows for better power transfer, giving the rider more precise handling and improved stability.

5.4 Thru-Axle vs. Quick Release : Compatibility with Disc Brakes

Quick releases can sometimes lead to brake rub when used with disc brakes. The quick release design and installation method make it harder to ensure precise alignment between the disc rotor and brake caliper during wheel installation. Additionally, slight movements or loosening of the quick release during riding can cause the rotor to rub against the caliper, affecting brake performance and the overall riding experience.

Thru-axles, with their closed fork holes, allow for more precise alignment between the rotor and caliper during wheel installation. The stability of the thru-axle system also minimizes the chances of brake rub during riding, ensuring that the disc brake system performs.

5.5 Thru-Axle vs. Quick Release : Ease of Installation and Removal

One of the main advantages of quick-release (QR) axles is their ease of installation and removal. They do not require any additional tools; simply rotating the quick-release lever allows you to install or remove the wheel quickly. This feature is particularly useful in situations where frequent wheel changes or minor adjustments are necessary, such as in urban riding when a flat tire requires a quick wheel replacement.

On the other hand, thru-axles are generally more cumbersome to install and remove. You usually need a wrench or similar tool to tighten or loosen the axle bolt. This makes the process more complex and time-consuming. However, for riding scenarios that demand peak performance and stability—like professional mountain biking races or high-intensity off-road activities—the performance benefits of thru-axles outweigh the convenience of quick installation and removal.

5.6 Thru-Axle vs. Quick Release : Weight Considerations

Typically, quick-release axles are lighter, which helps reduce the overall weight of the bike. For cyclists who are sensitive to weight or those who prefer lightweight bike types, such as road racers, this can be a significant advantage.

Thru-axles, due to their structure and material, are generally heavier than quick-release axles. However, with advancements in material technology, the weight of thru-axles has been gradually reduced in modern bicycle designs. Despite this, they are still usually a bit heavier than quick-release axles.

6. Choosing Between Thru-Axles and Quick-Release

To summarize, quick-release axles are lightweight, easy to install and remove without tools, and more affordable. Their drawbacks include lower rigidity and the potential for the quick-release lever to rub against the disc brake rotor, causing noise and loosening issues. Thru-axles, on the other hand, offer superior safety and rigidity. However, they are heavier, more complex to install, and more expensive.

It is important to note that for regular road cycling, the rigidity of a standard quick-release axle is usually sufficient. Even for moderate off-road riding, quick-release systems can perform adequately. You might not need a more rigid system to connect your fork and hub. If your current bike uses a quick-release system and you don’t plan on doing a lot of off-road riding, you can stick with your existing quick-release system. Not only is its performance adequate, but switching to a thru-axle would likely require purchasing a new fork, frame, and hub, which is far more than a $30 investment.

If you are selecting a new bike and are undecided between a frame designed for quick-release or one for thru-axle, it’s generally better to choose a thru-axle. Quick-release systems often encounter issues like noise from the quick-release lever rubbing against the disc brake rotor and occasional wheel loosening. Even with the additional weight and cost, a thru-axle is currently the best choice.

7. Solution: Thru-Axles with Built-in Quick-Release Levers

If you want the convenience of quick-release systems and the stability of thru-axles, there is an innovative solution available. Some thru-axle systems on the market come with a built-in quick-release lever. The quick-release mechanism is in the thru-axle shaft. When you don’t need to use the quick-release lever, you can tuck it inside the thru-axle. This design combines the advantages of both systems: strong stability and tool-free installation and removal. Aside from being a bit more expensive, this design has not yet shown any significant drawbacks.

By the way, SUMLON has been manufacturing bicycle parts for over 15 years. Contact us if you are looking for a bike parts factory or a one-stop wholesaler. Peace