1.Bike power meters explained: crank arm, pedal and spider-based

Bike power meters help track your real-time power output during cycling. The average power output over a ride reflects a rider’s fitness level. Three main types are crank arm power meter, power meter pedals, and spider-based power meter. Each has its pros and cons regarding accuracy, convenience, and other factors.

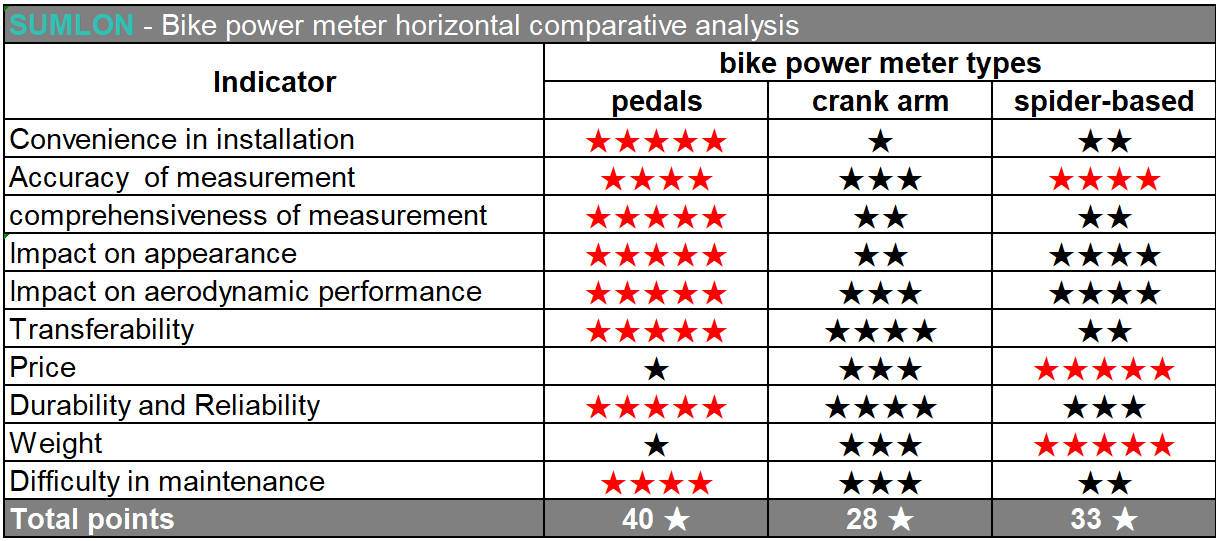

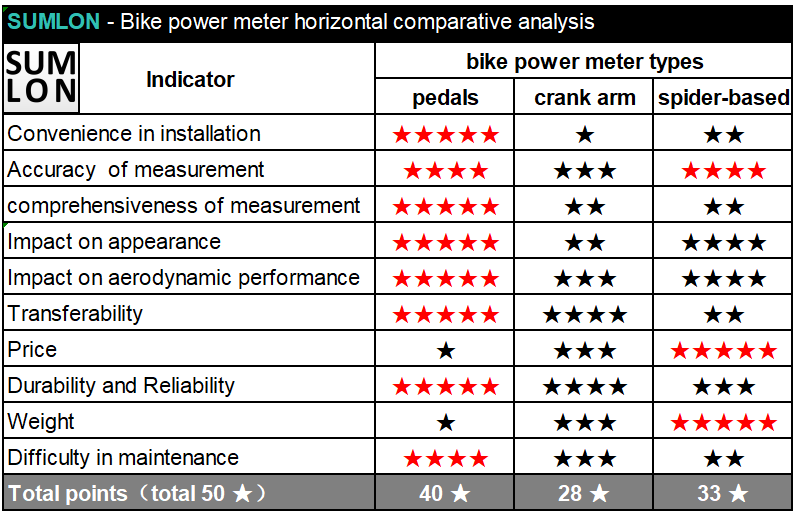

In conclusion, power meter pedals may be the best overall choice. The following table gives an overview of how these power meters perform across different metrics.

1.1 Convenience in Installation

Power meter pedals are straightforward to install. You simply remove the existing pedals and install the power meter pedals. Spider-based power meters require removing the chainring and installing the power meter components. This process is a bit more complex. Crank arm power meters attach to the crank arm, and installation often involves removing the crank, which can be the most complicated process.

1.2 Accuracy of Measurement

It’s hard to rank the three types definitively in terms of accuracy. However, power meter pedals and spider-based power meters tend to be more accurate. Crank arm power meters may be slightly less accurate because they rely on different technology.

1.3 Comprehensiveness of Measurement

Power meter pedals usually provide the most detailed data. They can measure the pressure exerted by each foot, pedal stroke force, cadence, and the balance between left and right legs. This data helps cyclists analyze their pedaling technique and make adjustments for balanced training.

1.4 Impact on Appearance

Power meter pedals look much like regular pedals and don’t alter the bike’s appearance much. Spider-based power meters are somewhat noticeable on the chainring, though subtle. Crank arm power meters tend to be bulkier and may affect the bike’s overall appearance, especially if they don’t match the crank’s size or color.

1.5 Impact on Aerodynamic Performance

None of the three types significantly affects aerodynamics. Power meter pedals are the least likely to interfere with airflow. Spider-based power meters may disrupt airflow around the chainring slightly. Crank arm power meters, located in a more prominent position on the bike, could increase drag due to their added bulk.

1.6 Transferability

Power meter pedals are the easiest to transfer between bikes. You can move them as long as the pedal spindle fits the new bike’s crank arm. Crank arm power meters may require adjustments since crank specifications vary between bikes. Spider-based power meters are the hardest to transfer, often requiring changes to the chainring or other parts due to compatibility issues.

1.7 Price

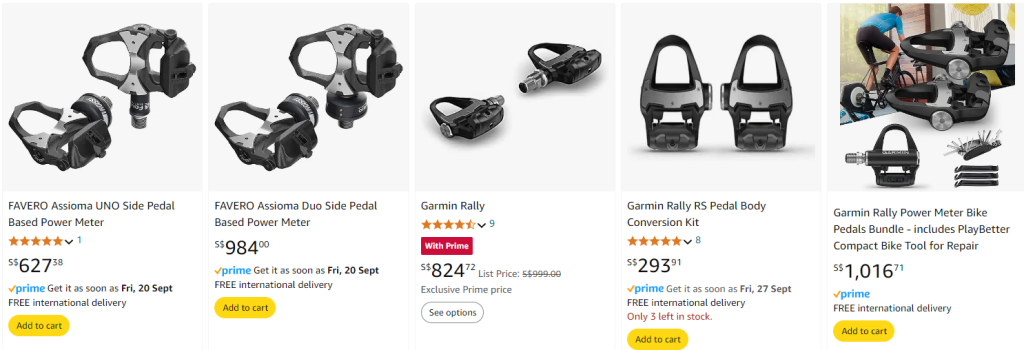

Power meter pedals are usually the most expensive due to their advanced technology and high-precision sensors. Crank arm power meters tend to be slightly cheaper because they involve simpler tech and manufacturing processes. Spider-based power meters are often the least expensive, with a more straightforward design.

1.8 Durability

Power meter pedals are generally durable and less prone to failure. Their sensors are in stable environments, reducing the risk of issues. Crank arm power meters, installed on the crank, may experience more vibration and shock. Spider-based power meters are vulnerable to wear from the chain and chainring movement, which can affect accuracy and reliability over time.

1.9 Weight

Power meter pedals tend to be heavier to normal ones due to their need for strength and durability. Crank arm power meters might weigh less as they integrate more seamlessly with the crank arm. Spider-based power meters are often the lightest, with a compact design that doesn’t include as many extra electronic components.

1.10 Difficulty in Maintenance

Power meter pedals are relatively easy to maintain. You usually just need to clean them and check the tightness of the connections. Crank arm power meters require more effort to uninstall and reinstall. They also face more forces during riding, meaning they need careful inspection. Spider-based power meters are the hardest to maintain. The chainring is a high-wear area, and you may need specialized tools and skills to service the power meter effectively.

Next, we will provide a detailed performance introduction of the advantages and disadvantages of these three types of bike power meters: crank arm power meter, power meter pedals, and spider-based power meter.

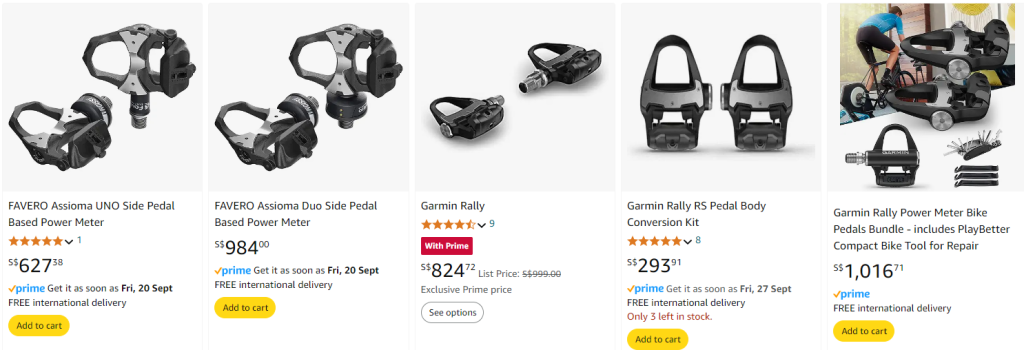

2. Power Meter Pedals – Bike power meters I

2.1 Advantages of Power Meter Pedals

2.1.1 Convenience in installation and use

Power meter pedals are generally easy to install. You don’t need to modify the crank or other complex parts of the bike. They are compatible with different bike types, including road bikes and mountain bikes. Many models use standard pedal threads, allowing for quick installation on the crank arm. Once installed, riders don’t need extra setup to start measuring power. You simply pedal as usual, and the power data is recorded automatically, allowing you to focus on the ride itself.

2.1.2 Accuracy and comprehensiveness

Power meter pedals measure the force and power output from each pedal stroke, offering detailed data on left and right leg power balance and pedaling smoothness. This helps riders analyze their pedaling technique and adjust for balanced leg strength. Compared to other power meters that might be affected by component friction or gaps, power meter pedals reflect the actual force applied to the pedals more directly, making the measurements highly accurate and comprehensive.

2.1.3 Minimal impact on appearance and aerodynamics

Power meter pedals, mounted at the pedal position, don’t alter the bike’s appearance like crank arm power meters or spider-based power meters might. For riders who value a sleek and clean bike look, this is a significant advantage. Additionally, power meter pedals usually don’t negatively affect the bike’s aerodynamic performance, as they don’t add noticeable drag. This is crucial for competitive riders or anyone focused on maintaining speed and efficiency.

2.1.4 Transferability and versatility

Power meter pedals are highly transferable. When changing bikes, as long as the pedal axle is compatible, you can easily move the power meter pedals to the new bike without needing a new power meter. This flexibility saves costs over time.

2.2 Disadvantages of Power Meter Pedals

2.2.1 Price

Power meter pedals are generally expensive. Their design and manufacturing require complex engineering to fit precision power measurement modules into the small pedal structure. Well-known brands can charge several times more than regular pedals, making them cost-prohibitive for budget-conscious riders.

2.2.2 Durability

Since power meter pedals are at the bottom of the bike, they’re more exposed to road conditions, like water, mud, and debris. These elements can damage the electronics and sensors, reducing the lifespan and accuracy of the pedals. In contrast, crank arm power meters and spider-based power meters, which are mounted higher up on the bike, face fewer external environmental factors and may be more durable in harsh conditions.

2.2.3 Installation and compatibility

Although generally easy to install, power meter pedals may have compatibility issues with certain bike types or unusual pedal axle specifications. Not all bikes fit every model of power meter pedals. Crank arm power meters and spider-based power meters have better compatibility across different bike frames and drivetrain systems, making installation smoother.

2.2.4 Weight

Power meter pedals need to integrate various sensors and electronic components, making them heavier than regular pedals. For weight-conscious riders, particularly racers aiming for maximum speed, the extra weight might affect bike handling and performance. Crank arm power meters and spider-based power meters often add less weight, especially in higher-end models where manufacturers prioritize lightweight designs.

2.2.5 Stability of measurement accuracy

Pedal movement during riding can be complex, with not just downward force but also side-to-side and twisting motions. These can sometimes interfere with the accuracy of power meter pedals, making the data less stable compared to crank arm power meters and spider-based power meters. Crank arm power meters measure force directly from the crank, and spider-based power meters are mounted in more stable positions within the drivetrain, leading to more consistent measurements.

2.2.6 Maintenance and upkeep

Power meter pedals are complex and exposed to the elements, making maintenance more challenging. You need to regularly clean the pedals to prevent dirt and debris from affecting the sensors. If there’s an issue with the electronics or sensors, professional repair may be needed, which can be costly. Crank arm power meters and spider-based power meters generally require less upkeep, and their simpler designs make self-maintenance easier, or at least less costly in terms of repairs.

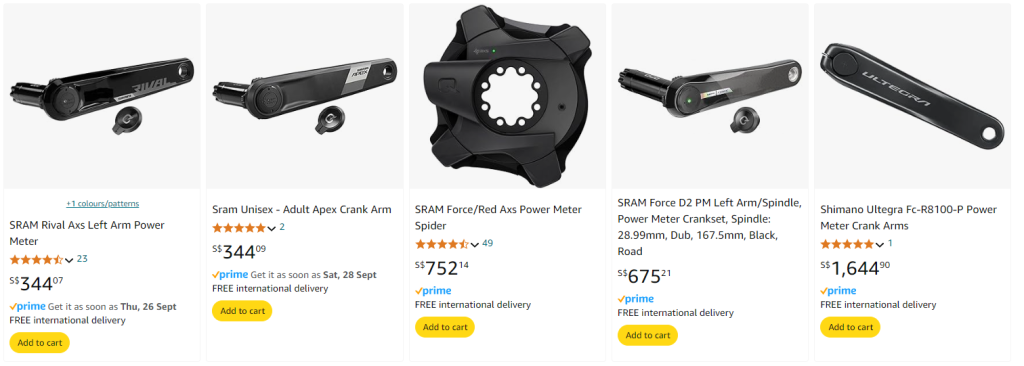

3. Crank Arm Power Meter – Bike power meters II

3.1 Advantages of Crank Arm Power Meter

3.1.1 Easy installation and wide compatibility

A crank arm power meter is usually installed on the bike’s crank arm. The installation process is simple and does not require major modifications to other parts of the bike. For users unfamiliar with complex bike assembly, swapping out the crank arm is relatively straightforward. Crank arm power meters are compatible with many different types of bikes, including road bikes, mountain bikes, and others. As long as the crank specifications match, it can be easily installed, offering broad compatibility.

3.1.2 Measurement accuracy and stability

The crank arm position allows the power meter to measure the force directly from the legs to the crank. This reduces errors caused by other factors, such as complex pedal movements or drivetrain gaps. Compared to power meter pedals, which may be affected by external disturbances, the crank arm power meter is more stable. It is less influenced by environmental factors like vibrations or mud, providing consistent and reliable power data. This is beneficial for long-term data analysis and training.

3.1.3 Minimal impact on appearance and aerodynamics

The crank arm power meter is relatively hidden, unlike external power meters that might increase wind resistance. It has little impact on the bike’s aerodynamics, which is especially important when riding at high speeds. This helps reduce unnecessary drag, improving riding efficiency.

3.1.4 Durability and reliability

The crank arm power meter has a simpler structure, with fewer exposed moving parts and electronics compared to power meter pedals. This makes it less prone to damage during regular use. It’s also less likely to suffer from direct impacts during bumpy rides or crashes. Its internal electronics and sensors are better protected from external factors like rain and dust, giving it greater durability and reliability. As a result, its lifespan tends to be longer, reducing the cost and inconvenience of frequent repairs or replacements.

3.1.5 Lower cost

Among various power meters, crank arm power meters are often more affordable, especially compared to high-end power meter pedals or spider-based power meters. For budget-conscious riders looking to train with power data, crank arm power meters offer a cost-effective solution. They meet basic power measurement needs without creating significant financial strain.

3.2 Disadvantages of Crank Arm Power Meter

3.2.1 Data accuracy

Crank arm power meters usually measure power from one side and multiply it by two to estimate total output. For riders with unbalanced left and right leg strength, this method may not be as accurate as power meter pedals, which measure each leg’s power separately. Riders needing detailed analysis of their left and right leg power differences for targeted training may find this limitation significant.

3.2.2 Measurement errors from position

While the crank arm measures leg force directly, the crank’s motion isn’t entirely uniform. There are slight rotations and wobbles during pedaling that can affect measurement accuracy. Spider-based power meters, installed at the crankset’s center, measure the torque of the entire drivetrain. This can provide a more comprehensive view of power output. Similarly, power meter pedals measure force directly at the pedal, offering a different advantage in accuracy.

3.2.3 Compatibility issues

Crank arm power meters are often tied to specific cranksets, bottom brackets, and bolt circle diameters. If you change to a different bike or have incompatible components, the crank arm power meter may not work without purchasing new accessories or even an entirely new power meter. This increases costs and hassle. Power meter pedals, by contrast, use a standard pedal thread and generally offer better compatibility across bikes.

3.2.4 Weight

To fit the power measurement module and electronics into the crank arm, crank arm power meters may be heavier than regular crank arms. For riders highly sensitive to weight, especially competitive cyclists, this extra weight could affect bike handling and speed. While high-end crank arm power meters have improved in lightweight design, they may still lag behind the lighter power meter pedals in this regard.

3.2.5 Cost and value

Although crank arm power meters are typically cheaper than high-end spider-based power meters, they are still more expensive than some affordable power meter pedals. For budget-conscious riders, crank arm power meters may still exceed their budget. Additionally, if a crank arm power meter malfunctions or breaks, the repair costs can be high.

3.2.6 Balance of features and price

Crank arm power meters may not offer as many advanced features as other types of power meters. For example, power meter pedals often provide additional features like cadence analysis and pedal stroke monitoring, which are valuable for improving technique and training. In comparison, crank arm power meters may have more basic functionality but still carry a relatively high price tag, making them less attractive in terms of value for money.

3.2.7 Installation and maintenance complexity

While crank arm power meter installation is generally simpler than spider-based power meters, it still requires some knowledge and tools. Correctly installing or removing the crank arm is necessary to ensure accurate power measurement. For riders unfamiliar with bike maintenance, this process can be challenging.

3.2.8 Higher maintenance demands

Because the crank arm power meter is installed on the crank, it is exposed to sweat, rain, and dust. Regular cleaning and maintenance are necessary to ensure accurate readings and proper function. If the crank arm power meter fails, repairing it often requires removing the crank arm, which can be complicated and may need professional assistance.

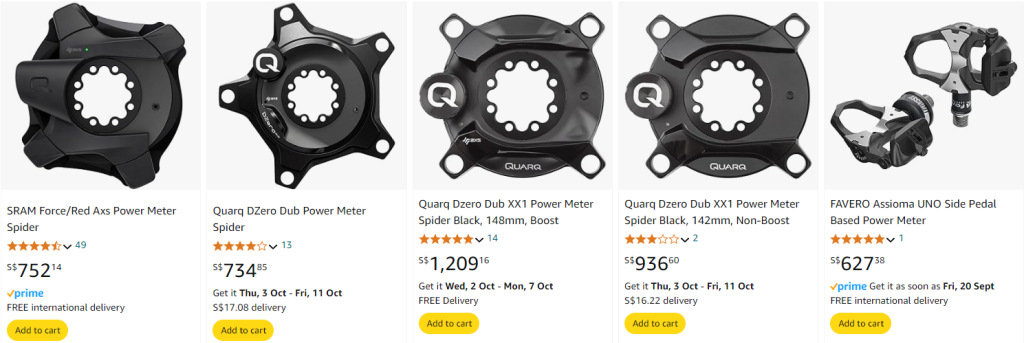

4. Spider-Based Power Meter – Bike power meters III

4.1 Advantages of Spider-Based Power Meter

4.1.1 Measurement accuracy

A spider-based power meter provides more comprehensive and accurate power output compared to crank arm power meters that estimate power or power meter pedals that measure force at the pedal. It offers reliable data, even in complex riding conditions, with less influence from external factors like vibrations or temperature changes. While power meter pedals may struggle with accuracy on rough terrain, and crank arm power meters can experience errors due to irregular crank movement, spider-based power meters are stable and deliver precise measurements.

4.1.2 Compatibility

Spider-based power meters are usually compatible with a wide range of bike frames, cranksets, and drivetrains. As long as the connection between the crank and chainring fits, it can be installed on road bikes, mountain bikes, and other types of bicycles. It also adapts well to upgraded or modified parts, making it easier to maintain accurate power readings when replacing chainrings or other components.

4.1.3 Easy installation and maintenance

Although it requires some professional skill and tools, installing a spider-based power meter is often simpler than installing complex power meter pedals or ensuring correct installation with crank arm power meters. The installation position is more accessible, and during regular maintenance, it’s better protected from environmental factors like mud or dust. Unlike power meter pedals, which require delicate care to avoid water or dust entering sensitive areas, spider-based power meters need less frequent and easier maintenance.

4.1.4 Rich data and functionality

Beyond basic power data, advanced spider-based power meters can provide additional metrics such as torque curves and pedaling efficiency. These data points help cyclists analyze their technique, optimize training, and identify areas for improvement. Many spider-based power meters are compatible with specialized software or training platforms, allowing for in-depth analysis and personalized training suggestions to enhance performance.

4.2 Disadvantages of Spider-Based Power Meter

4.2.1 Price

Spider-based power meters are more expensive due to their complex manufacturing process. High-precision sensors and electronics are required to measure torque accurately. As a result, their market price is higher compared to crank arm power meters and power meter pedals, which offer more affordable options, especially in their basic models.

4.2.2 Weight

The design of the spider-based power meter, with built-in sensors and electronics, adds weight to the bike. For riders focused on weight reduction, this added mass could affect speed and handling. Power meter pedals and crank arm power meters have made more advancements in lightweight design, with some high-end models balancing accuracy and reduced weight.

4.2.3 Installation and removal complexity

Installing a spider-based power meter requires precise work on the connection between the crank and chainring, often needing special tools and technical knowledge. Incorrect installation could impact power measurement accuracy or even damage the drivetrain. Removing it for maintenance or part replacements can also be cumbersome, requiring significant time and effort. In contrast, power meter pedals and crank arm power meters are easier to install and remove.

4.2.4 Limited left-right leg power data

Unlike power meter pedals, spider-based power meters cannot directly measure the power output of each leg. They rely on estimations to calculate left-right power balance. This limitation might not satisfy professional cyclists or those in specialized training programs who need precise left-right leg power data.

4.2.5 Compatibility issues

Spider-based power meters have specific requirements for cranksets, bottom brackets, and bolt circle diameters (BCD). They are not universally compatible with all bikes. To use the same spider-based power meter on different bikes, additional parts or adjustments may be needed, increasing the cost and complexity. Power meter pedals, on the other hand, offer more flexible compatibility across bike types, and crank arm power meters are also more adaptable in this regard. Additionally, spider-based power meters may face compatibility issues when upgrading chainrings or other parts, making them less convenient than power meter pedals or crank arm power meters.

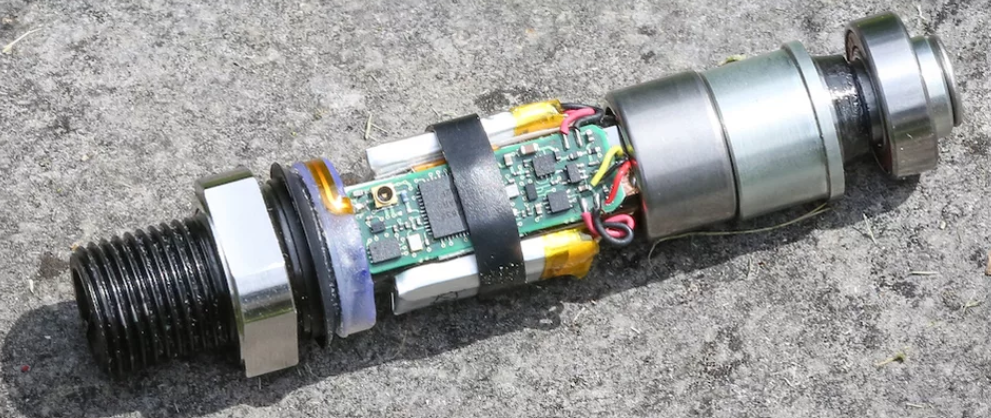

5. How a Bike Power Meter Works

5.1 What is Power and How is it Calculated?

In a bike’s drivetrain, your legs are the sole source of power. The force your feet apply to the pedals is what drives the bike forward. Power is the rate at which work is done, and can be calculated by multiplying force and velocity. For example, with power meter pedals, the sensor is located in the pedal spindle. It measures the force applied at the spindle and the velocity of the pedal’s movement. By multiplying the tangential force at the spindle and the linear velocity of the pedal, the system calculates power at that moment.

If you use a crank arm power meter, the sensor is on the crank arm. In this case, power is the force at the sensor’s position on the crank arm multiplied by the velocity of that point as it moves around the bottom bracket. Similarly, with a spider-based power meter, the sensor is installed on the crank spider. Power is calculated by multiplying the force at the sensor on the spider by its velocity around the center of the chainring.

5.2 How Bike Power Meters Measure Force at the Point of Contact

Power meter pedals measure the force you apply to the pedals and the direction of that force. The system splits this force into two components: one perpendicular and the other parallel to the pedal’s circular motion. And you use the parallel force to calculate power.

In the case of crank arm power meters and spider-based power meters, the sensor directly measures the tangential force along the circular path of the crank arm or spider. You don’t need any further processing to obtain the force used to calculate power.

5.3 How Bike Power Meters Measure Velocity at the Point of Contact

For power meter pedals, the system calculates the velocity of the pedal spindle. This process will use the length of the crank arm and your cadence. The velocity of the pedal spindle is the circumference of the circle described by the crank arm length (the distance from the pedal spindle to the bottom bracket) multiplied by your cadence in revolutions per second. For example, if you are using a 170mm crank arm and your cadence is 90 RPM (1.5 revolutions per second), the pedal spindle’s velocity is approximately 1.601 m/s (2 * π * 170mm * 1.5).

In crank arm power meters and spider-based power meters, you can also calculate the velocity based on the distance between the sensor and the bottom bracket, and the cadence. The calculation follows the same formula: the radius of the circle times the number of revolutions per second.

5.4 How to Calculate Final Power Output

As mentioned earlier, power is the product of the distance between the sensor and the bottom bracket (in meters), the number of revolutions per second, and the force applied in the tangential direction. For example, if your power meter pedals measure 90N of force in the tangential direction and the velocity of the pedal spindle is 1.601 m/s, your power output at that moment is 144.09 Watts (90N * 1.601 m/s).

By the way, SUMLON has been manufacturing bicycle parts for over 15 years. Contact us if you are looking for a bike parts factory or a one-stop wholesaler. Peace