We are going to go through several topics here, including (1) mechanical structure of all bike chain types, (2) common types of bike chains, (3) compatibility of different bike chain types, (4) backward compatibility with lower-speed cassettes, (5) 3 other classification methods for bike chain types, (6) how to choose a suitable new chain and (7) how to maintain the bike chain.

Mechanical structure of all bike chain types

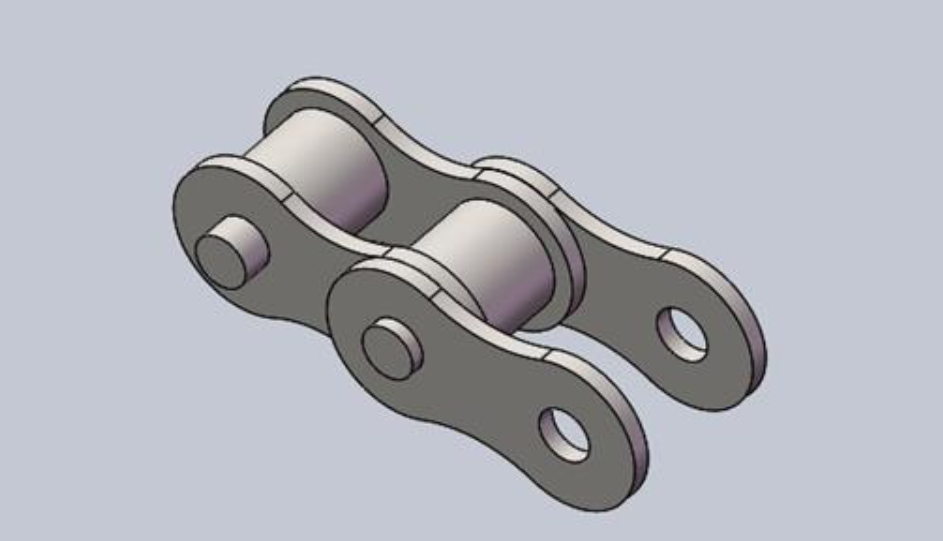

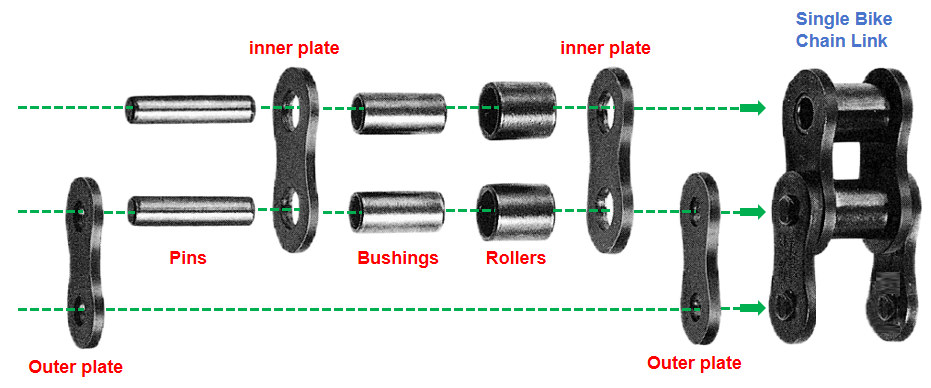

A bicycle chain forms a complete circle with over 100 identical chain links connected end to end.

Each single chain link consists of several small parts, including two outer plates, two inner plates, two pins, two rollers, and two bushings. You can refer to the image below to see how these components assemble into a bike chain link unit.

Common Types of Bike Chains

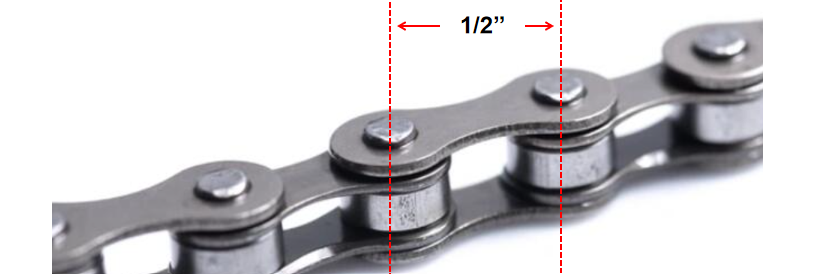

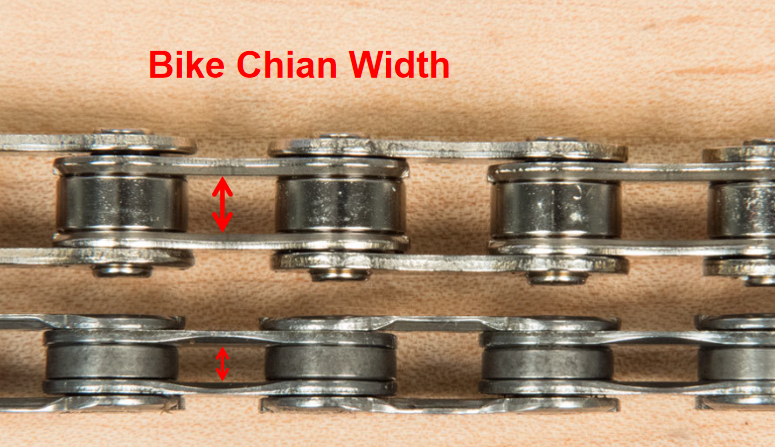

Three main types of bike chains exist: 1/2″×1/8″, 1/2″×3/32″, and 1/2″×11/128″. The first number (1/2″) represents the chain pitch, which is the distance between pin centers. This measurement is usually 1/2″. The second number indicates the chain width, or the space between the two inner plates. The market offers bike chains with widths of 1/8″ (3.175 mm), 3/32″ (2.381 mm), and 11/128″ (2.183 mm). These three chain widths encompass the entire range of bike chain types available.

Compatibility of Different Bike Chain Types

Mechanically, different bike chain types differ mainly in width. However, they are not interchangeable. This limitation arises from the evolution of bicycles, which introduced more speeds and narrower sprocket spacing. In the era of single-speed freewheels, the only bike chain type was the 1/2″×1/8″ chain, a globally accepted standard. As we developed 6-speed, 7-speed, 8-speed, and even 13-speed cassettes, the sprockets became thinner and more closely spaced. Using a chain that is too wide can cause it to rub against the sprockets.

Generally, you can pair the 1/2″×1/8″ bike chain with single-speed freewheels. For 5 to 8-speed freewheels, opt for the narrower 1/2″×3/32″ bike chain. If you have a 9-speed or higher freewheel, you will need the narrowest option, the 1/2″×11/128″ bike chain.

Backward Compatibility with Lower-Speed Cassettes

While different bike chain types are not strictly interchangeable, there is some compatibility. The widest 1/2″×1/8″ bike chain works primarily with single-speed freewheels. In contrast, the narrowest 1/2″×11/128″ bike chain can fit 12-speed cassettes as well as 7-speed and single-speed freewheels. Lower-speed freewheel sprockets have enough space to accommodate the narrower chain. Some people believe that choosing a narrower chain can help reduce the overall weight of the drivetrain and minimize friction and noise. However, these claims remain unproven.

3 Other Classification Methods for Bike Chain Types

Typically, we classify bike chains by their chain widths into 1/2″×1/8″, 1/2″×3/32″, and 1/2″×11/128″. You can also categorize them based on materials, surface treatments, and structural designs.

Base Materials

Bike chains can be divided based on the materials used. These include standard carbon steel chains, chromium-molybdenum alloy steel chains, nickel-chromium alloy steel chains, and stainless steel chains. Some high-end chains even use ceramic components.

Standard Carbon Steel: This material is cost-effective and meets general cycling needs. However, it offers poor corrosion resistance and lower strength.

Chromium-Molybdenum Alloy Steel: This alloy enhances hardness, wear resistance, and corrosion resistance. It withstands complex mountain trails and high-speed road conditions well.

Nickel-Chromium Alloy Steel: This material improves toughness, corrosion resistance, hardness, and wear resistance, providing a balanced performance.

Stainless Steel: This option significantly enhances corrosion resistance, though it has lower strength and hardness compared to alloy steels, leading to a slightly higher risk of breaking.

Ceramic Materials: High-end bike chains may use ceramic materials for components like rollers. Ceramic offers high hardness and low friction, effectively reducing wear and improving durability and transmission efficiency. However, it comes at a higher cost.

Surface Treatment Technologies

You can categorize bike chains based on various surface treatment technologies, including nickel-plated, chrome-plated, galvanized, oxidized, and phosphated chains.

Nickel-Plated Chains: Nickel plating effectively prevents rust and adds a shiny metallic finish, enhancing the bike’s appearance.

Chrome-Plated Chains: Chrome plating improves rust resistance and increases surface hardness. Chrome-plated chains also have a bright, decorative look.

Galvanized Chains: This low-cost rust prevention method provides basic protection against corrosion. You’ll often find galvanized treatments on lower-end bike chains.

Oxidized Chains: This process oxidizes the metal surface, forming a black oxide layer. While it doesn’t offer excellent rust protection, it gives the chain a unique black color.

Phosphated Chains: Phosphating creates a protective phosphate layer on the chain. This layer enhances rust resistance and serves as a carrier for lubricants. Applying oil to a phosphated chain helps the lubricant adhere better, improving performance.

Weight-Related Designs

\Bike chains come in standard and hollowed-out designs. High-end chains use materials with excellent hardness, toughness, wear resistance, and corrosion resistance. They often feature hollow inner and outer plates to reduce excess material and weight. Typically, a hollowed-out chain can be about 20 grams lighter than a standard chain.

How to Choose a Suitable New Chain

When selecting a new bike chain, follow these overall recommendations:

1. Choose the Right Type: Start by selecting a chain type that matches the width of your cassette’s speed.

2. Select Base Material: Within your chosen chain type, pick a base material based on your needs for toughness, corrosion resistance, hardness, and wear resistance. If you prioritize hardness and wear resistance but don’t need high toughness, consider a chromium-molybdenum alloy chain.

3. Consider Surface Treatment: Choose a surface treatment based on your rust protection and aesthetic preferences. If you like shiny chains, look for chrome-plated options.

4. Budget and Weight: Decide whether to invest in a hollowed-out chain based on your budget and weight requirements.

When to Replace the Chain

Knowing when to replace your chain is straightforward. A bike chain gradually stretches with normal use. You should consider replacement when the stretch reaches about 0.5% to 1%. Use a specialized tool to measure chain stretch. For example, if a 12-inch section of chain stretches more than 1/16 to 1/8 inch, it has stretched significantly. A stretched chain can cause poor engagement with the gears and may lead to skipping, which can result in accidents.

How to Maintain the Bike Chain

A bike chain wears down over time, so regular maintenance is crucial. To prevent excessive wear, lubricate the chain regularly. It’s generally recommended to lubricate every 100 to 200 kilometers of riding. When applying lubricant, ensure it coats all the chain links evenly. You can drip lubricant onto the chain, then rotate the pedals to allow the chain to move. This helps the oil penetrate the links thoroughly.

By the way, SUMLON has been manufacturing bicycle parts for over 15 years. Contact us if you are looking for a bike parts factory or a one-stop wholesaler. Peace