full guide: Bottom bracket Types & Standards

We have seen so many bottom bracket types and standards. Most of them are still being widely used today. Suppose you are trying to explore all the bottom bracket types/standards, and how the bottom bracket types/standards have been evolved from generation to generation, you will probably find the answers here.

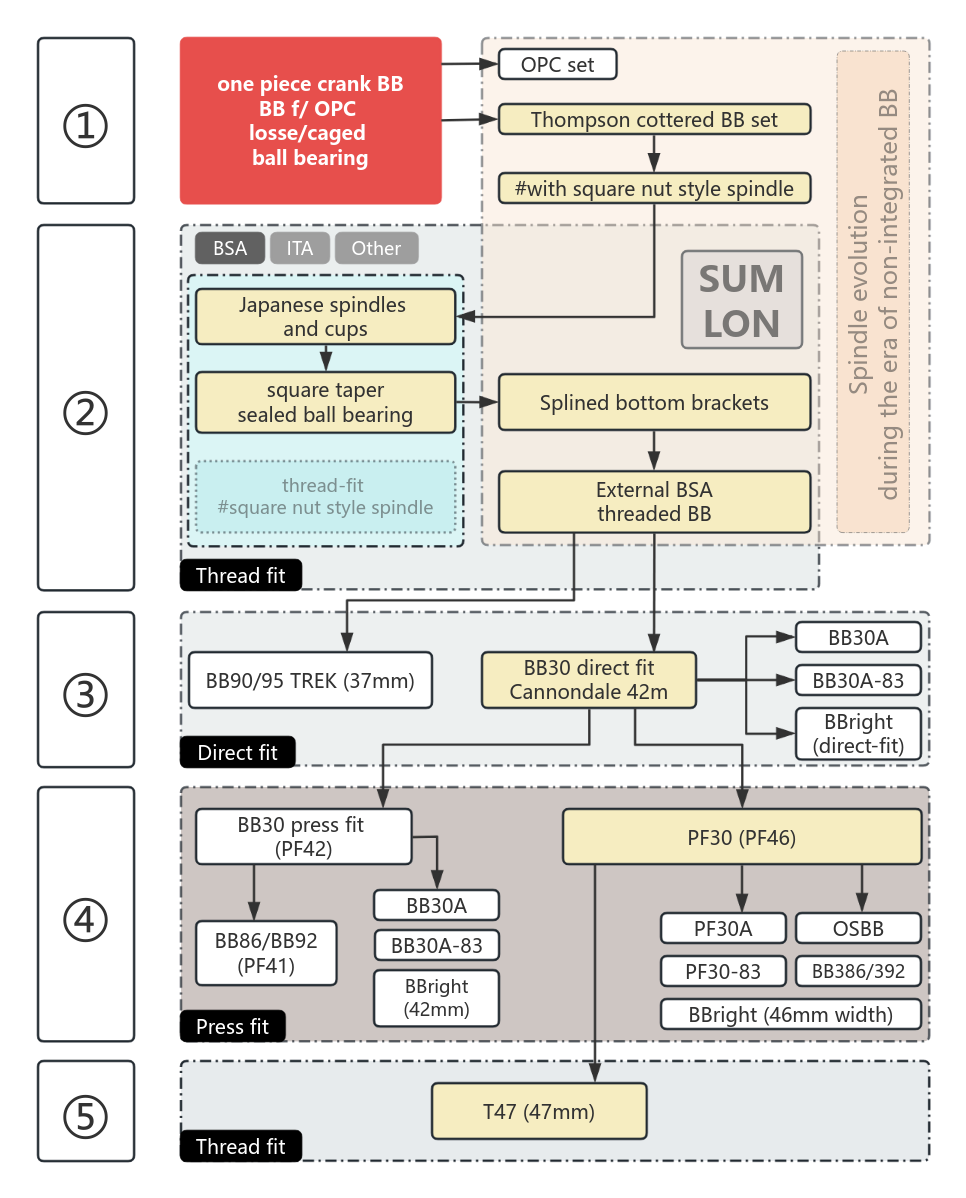

This diagram contains all the commonly used bottom bracket types/standards since the emergence of bicycle bottom brackets, as well as the upgrade/evolution path for all types of bottom brackets:

In the following context, based on the diagram above, I will introduce every single bottom bracket type/standard and how the types/standards have been updated and evolved from generation to generation. Regarding performance, T47 is far superior to the original BB for OPC. The structural upgrades from BB for OPC to T47 were not completed in a day. Let me briefly introduce how the bottom bracket has gradually evolved from its original simple structure to its current state through one and another slight changes in the detailed structure.

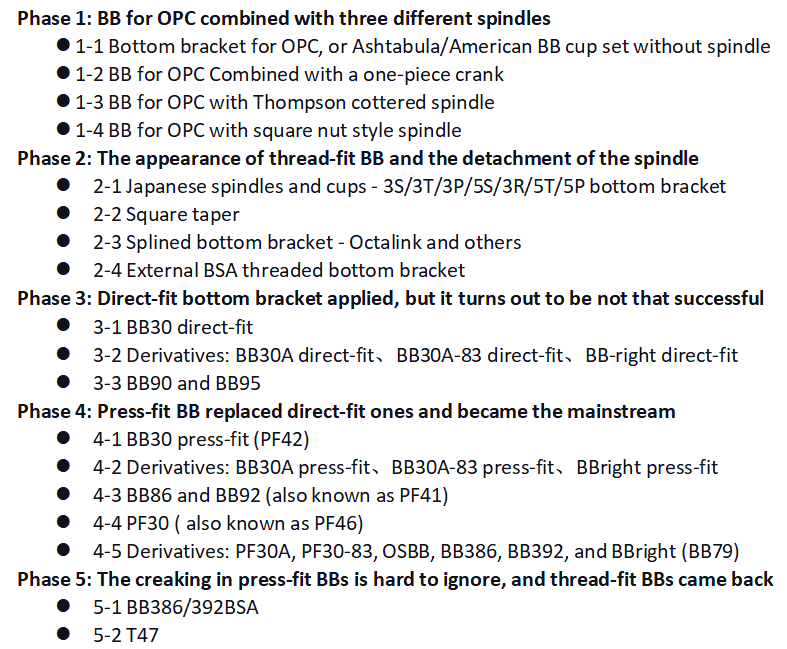

Here is a guide for the evolution history of bottom brackets and what we are going to discuss in the following context:

Phase 1:BB for OPC combined with three different spindles

We will start with the first generation of bottom brackets, called bottom brackets for one-piece crank (BB f/ OPC). There are 2 versions of it, one with caged bearings and the other with sealed bearings. They look like this when they are disassembled, including cups, bearings, cones, washers, and a locknut.

BB for OPC has many other names, including one-piece crank bottom bracket, American Bottom bracket, Ashtabula bottom bracket and cup and cone bottom bracket. BB for OPC is almost the most ancient version of the bottom bracket system ever existed. But it’s still widely used and works well in low-end bicycles & BMX bikes. It’s cheap and easy to manufacture.

A one piece crank bottom bracket can be mounted/combined with several kinds of spindles. The most commonly seen combinations are BB for OPC with one-piece crank, with Thompson cottered spindle, and with square nut style spindle. BTW, unlike BB86 or T47 with a short bottom bracket type name, these combinations have very long names, which means that if you would like to quote these combinations, you will have to use the long phrase such as bottom bracket for OPC with square nut style spindle. In case you want to see how they respectively look like:

with one-piece crank

with square nut style spindle

with Thompson cottered spindle

Under ‘BB for OPC’ bottom bracket standard, the bottom bracket for OPC only fits the frame shells with 51.5/43 mm inner diameter (ID) and 68/73 mm shell width.

Phase 2: Thread-fit BB and the detachment of spindles

(1) Japanese spindle and cups, a.k.a. 3S/3T/3P/5S/3R/5T/5P bottom bracket

A. common sense – small changes in bottom bracket types evolution

Before we look into the next generation of BB for OPC, here is a common sense about all 10+ generations of bike bottom brackets that there will only be one small new structural design upgrade from generation to generation. The structural design upgrades could be the connection between the spindle and the cranks (cottered, square taped, or splined), the connection between the bearing cone and the bearing cup (loose bearing, caged bearing or sealed bearing), and the connection between the cups and the BB shell (thread-fit, direct-fit or press-fit).

B. Japanese spindle and cups

After knowing the three combinations (bottom bracket for OPC + different spindles) mentioned above, let’s focus on the BB for OPC with square nut styles spindle among them. Based on the first-generation BB system, which is BB for OPC with square nut style spindle, engineers’ first thought was to improve the connection between cups and BB shells, upgrading it from press-fit to thread-fit. Boom, here it is—Japanese spindle and cups.

C. Why Japanese spindle and cups making these upgrades?

This new design (from press-fit to thread-fit) helps maintain the usability of the BB system after it is disassembled for maintenance. Without professional tools, cups in old version of BB for OPC are not easy to remove from the BB shell. Even if dismantled, it will cause irreversible damage to the BB shell. The threaded cups will not have this issue.

Meanwhile, compared to BB for OPC, the bearing cones in the Japanese spindle and cup system have been integrated into the spindle. The removal of independent cones resulted in a significant reduction in costs. The factory only needs to squeeze out two circular structures during the production of spindles to serve as bearing cones.

D. ‘Bottom bracket standard’ and ‘bottom bracket type’ are different concepts

In most circumstances, ‘Bottom bracket types’ and ‘bottom bracket standards’ share the same name. For instance, ‘Japanese spindles and cups’ is both the name of a bottom bracket standard and a bottom bracket type. But ‘Bottom bracket types’ and ‘bottom bracket standards’ are different concepts.

When we talk about bottom bracket standards, we are discussing the structural design and detailed parameters during manufacturing. While when we talk about bottom bracket type, we are more like discussing the name of these products, and it is what you use as keywords to search in google when you would like more information about this product. In most situations, you don’t have to distinguish them.

E. ‘Japanese spindles and cups’ as Bottom bracket standard and type name

‘Japanese spindles and cups’ is a bottom bracket standard. The corresponding frame shell standard is called BSA or ISO, which specifies a shell width of 68/70 mm and 1.37 in*24 TPI threaded shell inner face. Under ‘Japanese spindles and cups’ standard, the bottom bracket fits a BSA threaded BB shell and has a Japanese spindle, two threaded cups, and caged ball bearings.

‘Japanese spindles and cups’ is also the bottom bracket type name. The 3S/3T/3P/5S/3R/5T/5P bottom bracket are the more specified type names. Taking 3S BB as an example, it has 49+50+46 mm spindle length, 16 mm spindle OD, and two 1.37 in*24 TPI threaded cups.

(2) Square taper -one of the most common bottom bracket types

A. Evolution from ‘Japanese spindles and cups’ to ‘square tapers’

Among all the bottom bracket types, the square taper is one of the most common bottom brackets. The square taper is upgraded from Japanese spindles and cups. The Japanese spindle and cups system and the square taper are products of two different eras. But please trust me, they are basically identical.

B. Difference between ‘Japanese spindles and cups’ and ‘square tapers’

From a structural perspective, you can see almost no difference between the Japanese spindle and cups system and the square taper. The difference between them is that the bearings have been changed from caged/loose ball bearings to sealed bearings, and the manufacturer added a sleeve between the two cups for waterproofing and dust prevention.

Due to the application of sealed bearings, there are several small structural changes. Compared to the loose/caged ball bearing system, which requires cones and cups as inner and outer races, the sealed bearing comes with inner and outer races for the balls. So, after applying sealed bearing, the cup and cone no longer have to be used as races. So, the manufacturer completely removed the protruding structure that initially served as a cone on the spindle and transformed it into a simple limit structure that restricted the movement of the sealed bearing. The interior of the Cup is no longer curved but only serves to fix the remaining parts, ensuring they stay inside the BB shell.

C. ‘Square taper’ as bottom bracket standard and bottom bracket type name

Square taper is both bottom bracket standard and bottom bracket type name. The corresponding frame shell standard is BSA/ISO threaded, which specifies a 68/73 mm shell width, 1.37 inch BB shell ID, and 1.37 in*24 TPI threads.

Under square taper BB standard, we can find so many different types of bottom brackets. They have different spindle lengths, such as square taper for 110.5/113/118/120/122.5/124.5/126/127.5 mm spindle length. Manufacturers will not assign a name to each square taper with a different spindle length. Just use “square taper + (shell width) + (spin length)” as the keyword when you try to look for the specific square taper on Amazon. For instance, use ‘square taper with 113 mm spindle‘.

(3) splined bottom bracket – bottom bracket types originally from Shimano

A. Evolution from square taper to Shimano Octalink

Before the appearance of Octalink, the diameter of the spindle was always 16 mm. Increasing the diameter of the spindle is considered an effective way to improve the overall stiffness of the BB system. For this reason, Shimano launched one of its own bottom bracket types Shimano Octalink based on the square taper. Octalink replaced the 16 mm spindle with a 22 mm hollow spindle. 8 splines on the 2 spindle ends are used to increase the joint capacity of the connection between the spindle and the cranks. As you can see, the differences between square taper and Shimano Octalink are the diameter of the spindle and the 8-spline design at both ends of it.

B. Other splined bottom brackets all have splines and spindles with bigger OD

You can tell from its name that Shimano Octalink has 8 spines. Other manufacturers then launched ISIS bottom brackets (10 lines) and Power Spline bottom brackets (12 lines) to avoid Shimano’s patents. These bottom brackets are collectively referred to as splined bottom brackets. (see above)

C. Splined bottom bracket as bottom bracket standard

Splined bottom bracket is a bottom bracket standard. The corresponding frame shell standard is also BSA/ISO, defined as BB shells with 68/73 mm shell width, 1.37 in*24 TPI threads, and 1.37 inch shell ID. Splined bottom bracket standard definition: a bottom bracket system that fits a BSA threaded BB shell and contains a splined spindle, sealed bearings, thread-fit cups, and a sleeve.

D. Splined bottom bracket as bottom bracket type name

Splined bottom bracket is the name of a general bottom bracket type which has splines on spindle ends. According to the different number of splines, there are more specific types of splined bottom brackets, which are Octalink (8 splines), ISIS Bottom bracket (10 splines), and Power Spline Bottom bracket (12 splines).

(4) External BSA threaded BB – bottom bracket types developed from splined BBs

A. Evolution from ‘splined bottom bracket’ to ‘external BSA’

During the development history of all bottom bracket types and standards, the appearance of splined bottom brackets has made cyclists realize the importance of increasing the diameter of the spindle. To further increase the outer diameter of the spindle, a new bottom bracket standard that fits spindles with larger OD has been introduced to the market.

B. Main difference between ‘external BSA’ and ‘splined bottom bracket’

Under the new bottom bracket standard, engineers removed the spindle from the bottom bracket system and used more over-sized sealed bearings based on splined bottom brackets. Square tapers use 16 mm OD spindle, splined bottom brackets upgraded it to 22 mm. Then external BSA fit spindles with like 22-24 mm, 29 mm even 30 mm OD.

The new BB standard we are discussing here is the commonly used external BSA threaded bottom brackets. The emergence of external BSA-threaded BB is absolutely a milestone. Since then, almost all bottom brackets no longer contain spindles. Various manufacturers have also introduced larger diameter spindles, including SRAM GXP 22-24 mm spindle, Shimano 24 mm spindle, DUB 29 mm spindle, and Cannondale 30 mm spindle.

C. Spindles are not integrated in bottom bracket systems any more

Interestingly, the spindle did not become an independent commercial component. On the contrary, the spindle, chainring, and crank arm have become an entirely new combination. A rigid connection exists between the spindle, chainring, and drive side crank arm. The emergence of External BSA-threaded BB officially started a history of integrated BB.

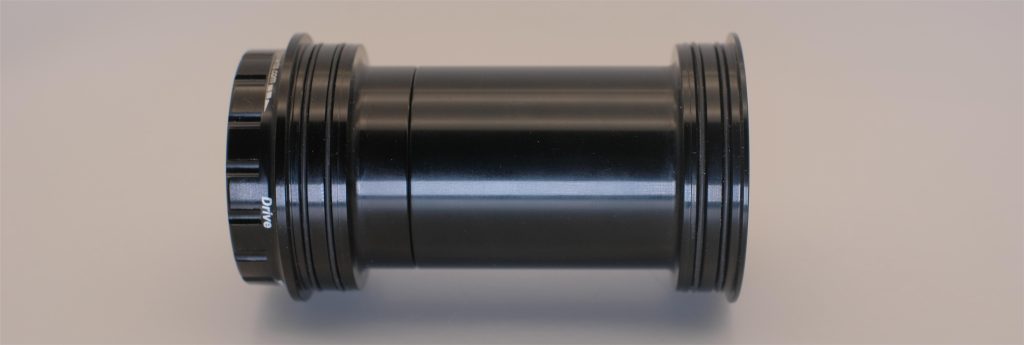

D. External BSA threaded BB as bottom bracket standard

This bottom bracket standard is called External BSA threaded BB or Outboard BSA threaded BB. The corresponding frame shell standard is BSA/ISO, defined as BB shells with 68/73 mm shell width, 1.37 in*24 TPI threads, and 1.37 inch shell ID. External BSA threaded BB standard definition: a bottom bracket system that fits a BSA threaded BB shell containing two threaded cups with bearings and a sleeve.

E. External BSA threaded BB as bottom bracket type name

External BSA threaded BB can be the general name for all external BSA threaded BB types. Speaking of bottom bracket types, external BSA threaded BBs can adapt to different spindle specifications, such as GXP(22-24 mm)/24 mm/DUB(29 mm)/30 mm. So the more specific BB type names would be BSA-24, BSA-DUB, and BSA-30 and something like this. Please note that any one of them fits 68/73 mm shells without worrying about the shell width, because you can use washers or choose different sleeve lengths.

Phase 3: Direct-fit applied in bottom bracket types, but not successful

(1) BB30 direct-fit and derivatives

A. Evolution from external-BSA to BB30 direct-fit

In 2006, the emergence of the BB30 direct-fit standard brought press-fit back to the bottom bracket types family. BB30 direct-fit is a bottom bracket standard jointly promoted by Cannondale and FSA. This is a straightforward bottom-bracket system. The parts are two sealed bearings, two retaining clips, and some dust covers and washers. This system allows cyclists to use a 30 mm ultra-large spindle while significantly reducing the weight of the entire BB. So, the 30 in the BB30 direct fit standard refers to Cannondale’s BB system using only 30 mm spindles.

B. BB30, BB30A, BB30A-83, and BBright direct-fit: use the same bottom bracket kit

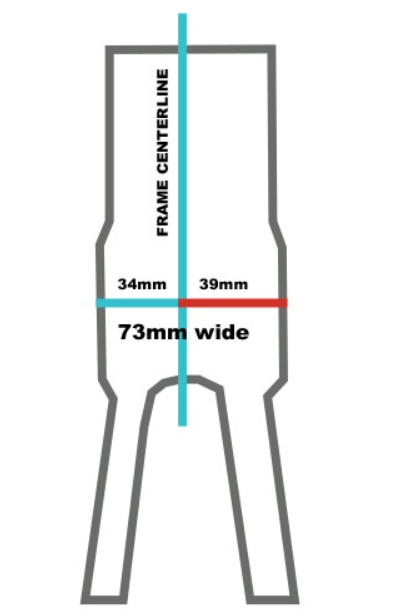

Following the same concept that put the bearings directly into the bottom bracket shell on the frame, Cannondale developed one of its own bottom bracket types BB30A direct-fit standard and the BB30A-83 direct-fit standard. Cervelo launched a similar BBright direct-fit standard.

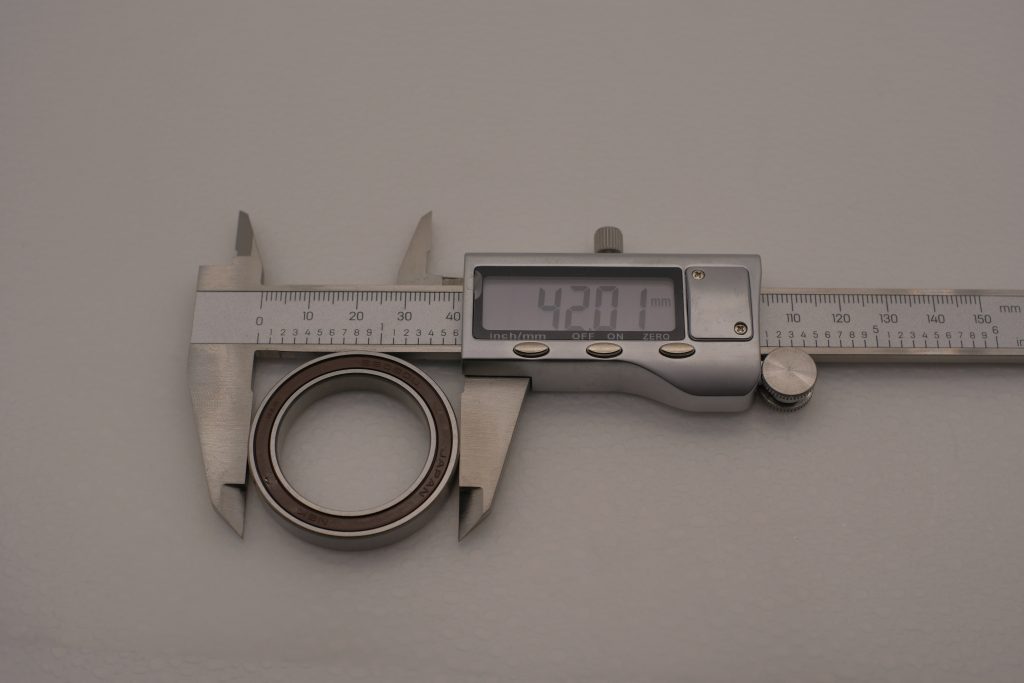

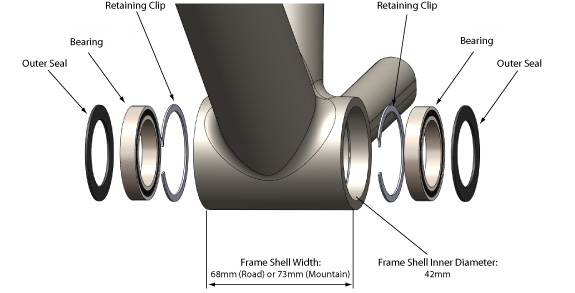

It is interesting that under BB30 direct-fit and its multiple derivative standards (BB30, BB30A, BB30A-83, and BBright direct-fit), the bottom brackets them-self are the same. That is to say, even if BB30, BB30A, BB30A-83, and BBright direct-fit bottom brackets are developed by different brands, have different standard names and designed for different frame shell widths, they are actually the same thing which include two 42*30*7 mm bearings and 2 clips, or you can also call it the direct fit-30 bearing kit.

C. BB30 (and derivatives) as bottom bracket standard

BB30 direct-fit and its derivative standards, such as BB30A direct-fit, BB30A-83 direct-fit, and BB-right direct-fit, are all bottom bracket standards. They correspond to different frame shell standards. The frame shell standard corresponding to the BB30 direct-fit bottom bracket standard is a direct-fit shell with 42 mm shell ID and 68 mm road / 73 mm MTB shell width. The frame shell standards corresponding to BB30A direct-fit, BB30A-83 direct-fit, and BB-right direct-fit specify different shell widths of 73 mm (normal 68 mm road bike shell width + 5 mm on the drive side), 83 mm, and 79 mm respectively.

So the definition of BB30 direct-fit standard is a bottom bracket system that fits the press fit shell with a 42 mm shell ID and a 68/73 mm shell width, and it contains only two 6806 sealed bearings and clips. Except for shell width, BB30A direct-fit, BB30A-83 direct-fit, and BB-right direct-fit have similar standard definitions.

D. BB30 (and derivatives) as bottom bracket standard

As discussed above, under these standards, we use the same bottom bracket type: the 6806 bearing and clip kit (42*30*7 mm bearings + clips), or you can also call it the direct fit-30 bearing kit.

(2) BB90 and BB95 – direct fit bottom bracket types from TREK

A. From BB30 direct-fit to BB90/95

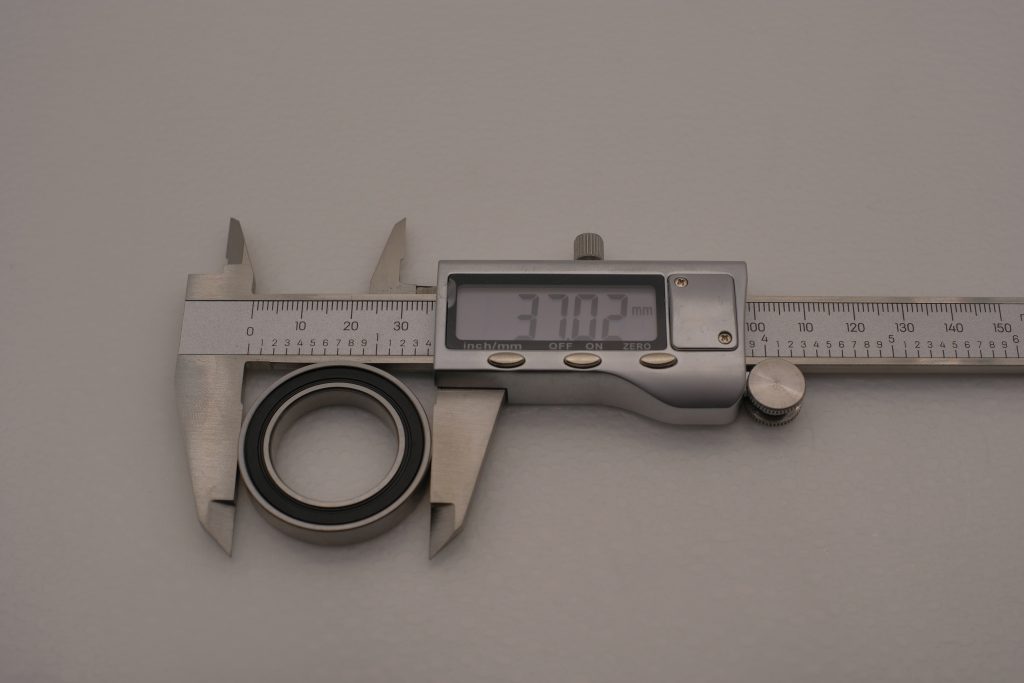

TREK developed its own direct-fit bottom bracket types and standards – BB90 standard and BB95 standard. They both press bearings with an outer diameter of 37 mm directly into the frame shell, like Cannondale’s BB30 direct-fit, BB30A direct-fit, BB30A-83 direct-fit, and BB-right direct-fit standards. However, the BB90/95 standard specifies different shell widths (90 mm/95 mm)and inner diameters (37 mm) . Moreover, the BB90/95 standard does not specify the use of clips.

B. BB90/95 as both bottom bracket standard and type name

BB90/95 is the bottom bracket standard. Its corresponding frame shell standard is a direct-fit BB shell with 37 mm shell ID and 90/95 mm shell width. So, the definition of BB90/95 is a bottom bracket system that fits the direct fit BB shell with 37 mm shell ID and 90/95 mm shell width and contains two sealed bearings directly pressed into the shell. The bottom bracket type name is BB90/95 as well.

C. Difference between BB90/95 and BB30, BB30A, BB30A-83, BBright direct-fit

Now you know all the direct-fit bottom bracket standards. They are BB30 direct-fit, BB30A direct-fit, and BB30A-83 direct-fit standards from Cannondale, BBright direct-fit standards from Cervelo, and BB90/95 standards from TREK. The first difference among them is that the BB shell ID corresponding to the BB30 direct-fit, BB30A direct-fit, BB30A-83 direct-fit, and BBright direct-fit standard is 42 mm, while the BB shell ID corresponding to the BB90/95 standard is 37 mm. The second difference is that BB30 direct-fit BB, BB30A direct-fit BB, BB30A-83 direct-fit BB, and BBright direct-fit BB use clips, while BB90/95 bottom bracket does not.

Phase 4: Press-fit BBs became the mainstream bottom bracket types

(1) BB30 press-fit (PF42) and derivatives

A. BB30 direct-fit and derivatives are not that good

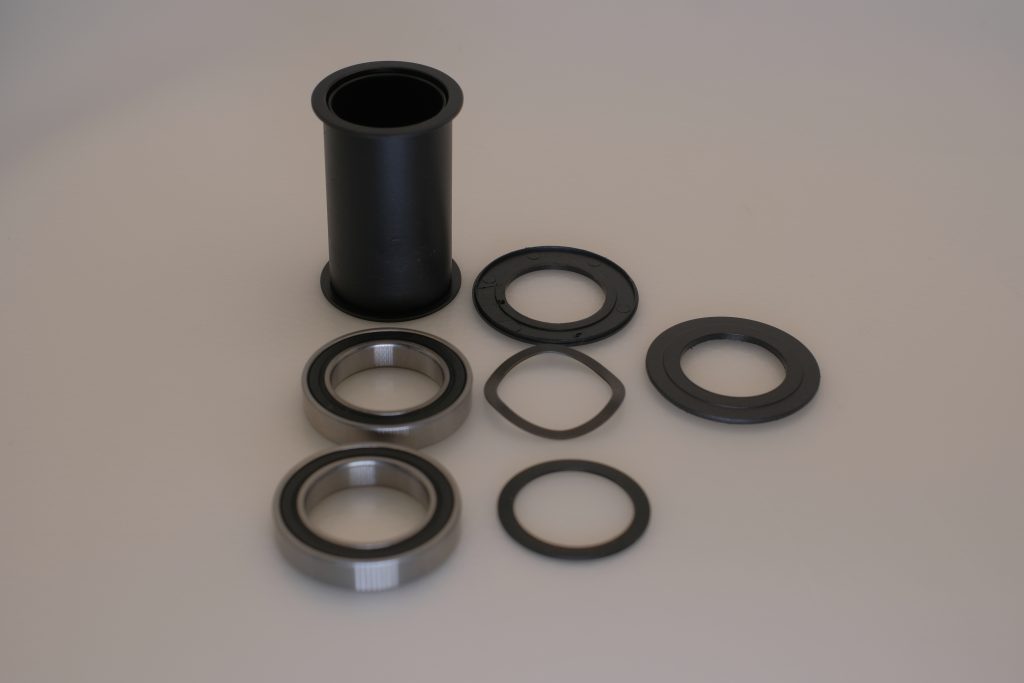

The BB30 direct-fit standard removed the bearing cup and pressed the bearings directly into the frame. In most people’s opinion, this design by Cannondale is not really successful. Direct-fit bottom brackets require extremely high precision in frame manufacturing, and direct-fit BBs are prone to causing abnormal noise and irreversible damage to the frame. So, a group of direct-fit bottom bracket standards represented by BB30 were ultimately replaced. Engineers have added bearing cups and sleeves to the direct-fit bearing and clip system.

B. Evolution from BB30 direct-fit to BB30 press-fit (PF42)

They developed a new bottom bracket standard called BB30 pressure-fit or PressFit-42 (PF42). The BB30 direct-fit standard and BB30 press-fit standard both specify that the inner diameter of the BB shell should be 42 mm, the shell width should be 68/73 mm, and BB30 pressure-fit supports a more over-sized spindle of 30 mm. The difference is that the BB30 press-fit standard bottom bracket has bearing cups and supports all spindle sizes of 24 mm, GXP 22/24 mm, DUB 29 mm and even 30 mm.

C. BB30 direct-fit and PF42 both belongs to a more general standard: BB30

You can disregard the distinction between BB30 direct fit and BB30 press fit. They all belong to a more significant standard, namely the BB30 standard. The frame shell corresponding to BB30 standard is press fit shell with 42 mm shell ID, and no shell width is defined. Any bottom bracket that fits the BB shell with 42 mm shell ID can be named BB30 bottom bracket, no matter whether it’s direct fit or press fit. Under the BB30 standard, we have BB30 direct fit, BB30A direct fit, BB30A-83 direct fit, BBright direct fit, BB30 press fit, BB30A press fit, BB30A-83 press fit, and BBright press fit standards, which correspond to different frame shell widths and have different ways to connect BB and frame shell. But overall, they will all be installed into BB shells with an inner diameter of 42mm.

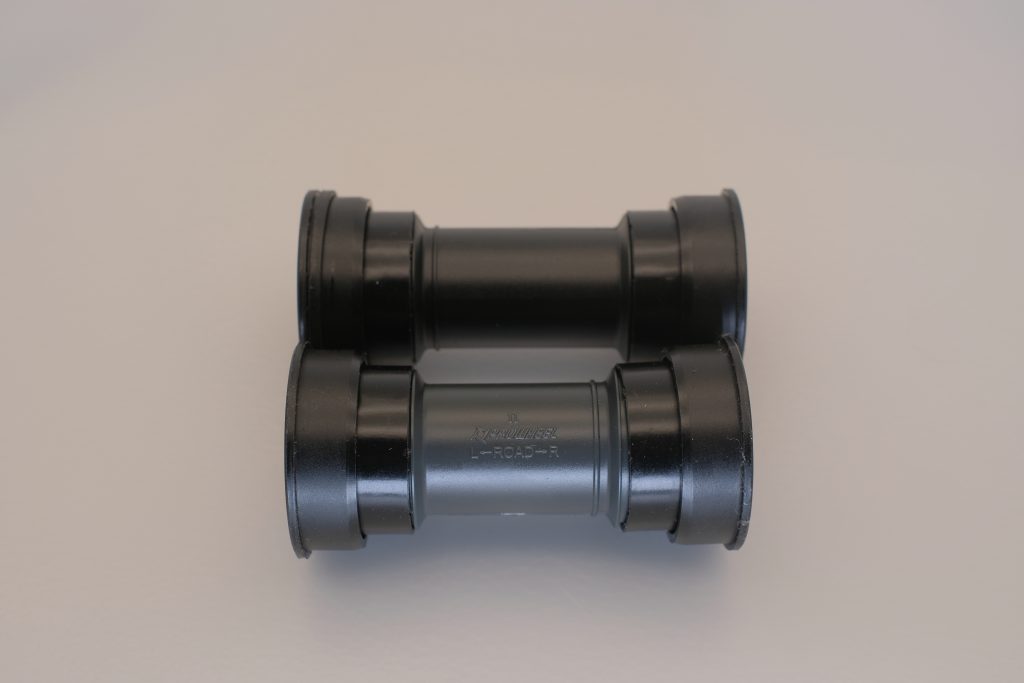

(2) BB86 & BB92 – PF41 from Shimano

Benchmarking BB30 press-fit BBs, Shimano introduced its PF41 bottom bracket standard. The PF41 standard includes two sub-standards, BB86 and BB92. The frame shells corresponding to the BB86 standard and BB92 standard are press-fit shells with 37 ID and 86.5/91.5 mm shell width, respectively. So, the BB86 bottom bracket is a bottom bracket that fits the press-fit shell with 37 ID and 86.5 mm shell width and contains 2 bearings, which are pressed-in composite or aluminum cups (37 mm OD) that are, in turn, pressed into the frame. Meanwhile, BB86 and BB92 are also bottom bracket types.

(3) PF46 (aka PF30) from SRAM and its derivatives

A. Evolution from BB30 direct-fit to PF46 (PF30)

In fact, the PF46 (PF30) standard is not an improved version of the BB30 press-fit standard. Instead, it was introduced on the basis of BB30 direct-fit standard directly. It was launched in 2009, which is a bit earlier than the BB30 press-fit standard, to solve the problems of the BB30 direct-fit bottom bracket system. Just like the BB30-press-fit standard, PF46 presses the bearings in cups and then presses the cup into the frame. The launch of PF46 bottom bracket system aims to address the strict dimensional tolerances and related manufacturing cost issues of BB30 direct-fit BBs. The only difference between PF46 and BB30 press-fit is that the PF46 standard adopted a 46 mm cup OD instead of 42 mm.

B. PF46 as bottom bracket standard and bottom bracket type name

PF46 is a bottom bracket standard. Under its corresponding frame shell standard, the BB shell should be a press-fit shell with 46 mm shell ID and 68 mm road/73 mm MTB shell width. So, the PF46 standard defines a bottom bracket that fits the press-fit shell with 46 mm shell ID and 68 mm road/73 mm MTB shell width and contains 2 bearings which are pressed-in composite or aluminum cups (46 mm OD) that are, in turn, pressed into the frame. BTW, PF46 is the bottom bracket type name as well.

C. Derivatives of PF46

PF46 (PF30) standard has several derivatives. We have PF30A, PF30-83 (PF30Ai), OSBB, BB386/BB392 and BB-right for 46mm shell ID. There is not much difference between them and the PF46 standard. The difference lies only in the fact that these derived standards correspond to different widths of the BB shell. Take PF30A as an example. It corresponds to a frame shell standard that BB shell should be a press-fit shell with 46 mm ID and 73 mm road/78 mm MTB shell width, which is 5 mm wider on the non-drive side than that in PF46 standard.

The same applies to other derived standards. PF30-83 (PF30Ai) adopted 83 mm shell width. OSBB adopted a 61 mm shell width. BB386 adopted 86.5 mm shell width. BB392 uses a 91.5 mm shell width. And BB-right for 46mm shell ID uses 79 mm shell width.

Phase 5: thread-fit BBs came back

Since the emergence of BB30 press-fit, press-fit has become the mainstream. Thread-fit has faded out of people’s sight for a long time. Threads have recently returned due to their advantages, such as low noise and easy maintenance. There are still not many new thread-fit standards and products available. We are going to talk about BB386BSA, BB392BSA, and T47 here.

(1) BB386BSA and BB392BSA

The BB386BSA/BB392BSA bottom bracket types and standard are not entirely new types and standards, and they are essentially external BSA threaded BB standards with a specific shell width. Under their corresponding frame shell standard, the BB shell should be a BSA threaded (1.37 in*24 TPI) shell with 86.5/91.5 mm shell width. So, under the BB386BSA/BB392BSA standard, the bottom bracket should be compatible with a BSA threaded (1.37 in*24 TPI) shell with 86.5/9.15 mm shell width and should be an external BSA threaded BB.

(2) T47

The T47 standard is an improved version of the PF46 standard. The only difference between T47 and PF46 is that under the T47 standard, the connection between BB and BB shell has been changed from press fit to thread fit precisely by adding a layer of 1 mm thread to the outer surface of the PF46 cup and turning the corresponding thread on the inner surface of the PF46 BB shell so that the BB shell can adapt to the cups with threads. By simply doing that, You will get a T47. The advantages of T47 bottom bracket are easy to maintain and reduces creaking. Of course, the T47 bottom bracket also brings some drawbacks, such as the risk of thread damage, causing the frame to be unusable.

By the way, SUMLON has been manufacturing bicycle parts for over 15 years. Contact us if you are looking for a bike parts factory or a one-stop wholesaler. Peace