What is Freewheel, and What is its Function?

A bicycle freewheel is a mechanical device on the rear wheel hub of a bicycle. Typically, you can see single-speed freewheels and multi-speed freewheels. Multi-speed freewheels usually have a series of metal sprockets stacked in size order.

In a traditional bicycle system, the force you apply on the pedals will go through the crank arm, chainring, chain, freewheel, hub, and spokes to the rear wheel, thus achieving rear-wheel rotation. In this transmission path, iIt connects the chain to the hub.

You might think that the chain could directly connect to the hub and drive its rotation. This is indeed possible, and bicycles with such a hub system are called fixed-gear bicycles. A characteristic of fixed-gear bicycles is that the entire transmission system, including the pedal, crank arm, chainring, chain, freewheel, hub, spokes, and rear wheel, is locked together. When the pedals rotate, they necessarily drive the rear wheel, and conversely, when the bicycle coasts forward by inertia, the rear wheel’s rotation also drives the pedals. This means that as long as the bicycle is moving forward, your feet must follow the pedal motion.

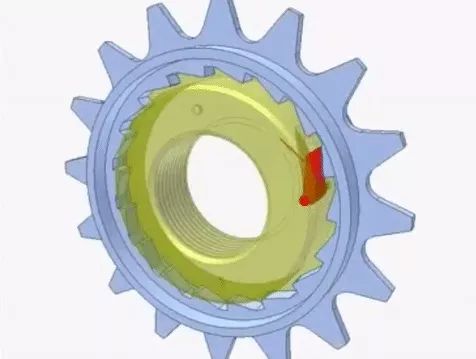

However, if we add a freewheel between the chain and the hub, the situation changes. The traditional one contains a ratchet mechanism, allowing the chain to transmit force to the hub and drive its rotation. But when the chain stops moving, the freewheel doesn’t impede the hub and rear wheel from continuing to rotate, enabling the bicycle to coast without pedaling. In other words, when you pedal, the force will go via the chain to the freewheel, which drives the hub’s rotation, thus moving the bicycle forward. When you stop pedaling, it allows the bicycle to continue coasting by inertia.

What is the Most Important Mechanical Structure in a Freewheel?

Without a doubt, the most important mechanical structure in a bicycle freewheel system is the ratchet mechanism. The ratchet mechanism allows the chain to effectively transmit power when it drives the freewheel to rotate in the forward direction, causing the rear wheel to turn and propel the bicycle. When the chain stops or rotates in the opposite direction, the ratchet mechanism allows the rear wheel to rotate freely, enabling the bicycle to continue coasting when pedaling stops, without the inertia causing the chain to drive the pedals backward.

In summary, the force from the pedals will go to the rear wheel, causing it to rotate when you pedal. But the force from the rear wheel cannot be transmitted back to the chain, chainring, and pedals. When you stop pedaling while riding, the ratchet mechanism ensures that the freewheel doesn’t transmit force backward. That allows you to take a brief rest while the bicycle continues to move forward by inertia. Additionally, in emergencies requiring braking, the ratchet mechanism prevents the freewheel from rotating backward, ensuring safety and stability during riding.

Thread-on VS Cassette

The traditional bicycle freewheel with an internal ratchet mechanism is known as a thread-on freewheel. However, many brands have introduced new designs, called cassette freewheels. Simply put, the traditional thread-on freewheel integrates the ratchet mechanism inside it and connects to the hub via threads. In contrast, the ratchet mechanism in cassette freewheels is located within the hub. And the cassette freewheel itself is simply a stack of sprockets. Its primary function is not to enable coasting through a ratchet mechanism but to provide gear shifting through different-sized sprockets.

Differences Between thread-on and Cassette systems?

thread-on and cassette freewheels are two different types of bicycle freewheels, with differences in structure, performance, price, and more.

From the perspective of structure

A thread-on bicycle freewheel attaches directly to the hub by threading onto it. The ratchet mechanism is inside it, rather than in the hub. Traditional single-speed freewheels also use this structure. However, you slide a cassette freewheel onto the splined freehub body (hub) and tighten it with a threaded lockring. The ratchet mechanism is inside the hub’s freehub body, and the cassette freewheel is just a stack of sprockets without any complex internal mechanisms.

In terms of performance

Thread-on freewheels are simple in structure, relatively inexpensive, and don’t require special maintenance. Traditional single-speed freewheels also use this structure. However, you slide a cassette freewheel onto the splined freehub body (hub) and tighten it with a threaded lockring. Additionally, thread-on freewheels typically have fewer gears (usually less than 7), and gear shifting is not very smooth, often causing noticeable jolts.

Cassette freewheels, on the other hand, offer higher power output, allowing for stronger acceleration and high-speed motion. They have a larger contact area with the axle, providing greater strength and reducing the likelihood of loosening or damage. Cassette freewheels typically have more gears (usually 8 or more), enabling smoother gear shifts with less jarring. However, cassette freewheels are more complex in structure, relatively expensive, and require more maintenance.

Speaking of dismantling

Thread-on bike freewheels connect to the hub through threaded connections, which makes the sprockets non-removable. If you brake a sprocket on a thread-on freewheel, you might need to replace the entire freewheel. In contrast, cassette freewheels connect to the hub via a spline and locking mechanism, allowing you to remove individual sprockets. If you brake a sprocket on a cassette freewheel,, you only need to replace that sprocket, not the entire freewheel.

When it comes to Bicycle Types

thread-on freewheels are commonly on single-speed bikes, climbing bikes, old-style geared bikes, and entry-level sport bikes, such as 6-speed or 7-speed bicycles. Due to their more stable structure, lighter weight, and ability to have smaller sprockets, cassette freewheels are commonly on mid-to-high-end modern sport bicycles.

In Summary

Thread-on hubs do not have a separate freehub body like cassette hubs, instead integrating the ratchet mechanism with the freewheel. Because the thread-on freewheel is attached via threads, as the number of gears increases, it becomes difficult to ensure accurate shifting since the threads are not aligned parallel to the direction of the wheel’s rotation.

Cassette freewheels separate the ratchet mechanism, integrating it directly into the freehub body, with the freewheel attaching to the splined freehub. In most circumstances, you can replace the cassette freehub independently. Compared to thread-on freewheels, cassette freehubs have more diverse ratchet and bearing structures, making them more adaptable to different needs. Additionally, the increased precision allows for smaller high-speed sprockets and more gear options.

Which is Better: thread-on or Cassette Freewheel?

Cassette freewheel is a better choice

SUMLON recommends choosing the cassette one, even though it might be more expensive. This system is newer and more technologically advanced. The main reason is that the connection between the cassette freewheel and the freehub is more stable. A thread-on freewheel connects to the hub via threads which are less than 10mm wide. This means that when using the smallest sprocket, the connection between the hub and the freewheel might wobble and increase power loss. This also means that thread-on freewheels cannot extend too far outward, as this could cause a disconnect between the freewheel and the hub. For this reason, thread-on freewheels cannot accommodate many gears or smaller sprockets.

The reason why we recommend cassette freewheel.

From a maintenance perspective, if the ratchet mechanism fails, you can simply replace the freehub body in a cassette system, but in a thread-on system, you would need to replace the entire system. Additionally, dismantling a cassette freewheel is relatively simple, requiring only specialized tools to remove each sprocket individually, whereas dismantling a thread-on freewheel is more complex and requires removing the entire system.

The cassette one has a simpler structure, needing only cleaning and lubrication of the sprockets and ratchet, while the thread-on freewheel’s ratchet mechanism inside the freewheel requires more careful maintenance to avoid damaging the ratchet. If you brake a single sprocket, you can replace only that sprocket instead of the entire freewheel. But a thread-on freewheel needs complete replacement, and this is more expensive. The maintenance cost of a cassette freewheel is relatively low due to its simple structure and ease of maintenance, while the maintenance cost of a thread-on is relatively high due to its complex structure and maintenance difficulty.

When Should You Replace Your Freewheel?

You should consider replacing your freewheel if you notice the following:

1)The teeth on it show obvious signs of wear, deformation or sharp edges. For instance, the height of the teeth is inconsistent or the tips of the teeth are very sharp.

2)After prolonged high-intensity use, the teeth on the freewheel can no longer mesh well with the chain, leading to frequent chain skipping or slipping while riding.

3)When pedaling normally, the chain often skips over its teeth, unable to transmit power smoothly. Chain skipping can severely affect riding continuity and stability.

4)The ratchet mechanism inside it malfunctions, for example, the bicycle cannot coast by inertia when pedaling stops, or abnormal backward pedaling causes the chain to drive the freewheel.

5)It has become severely rusted due to prolonged exposure to harsh environments, affecting its normal operation.

6)For multi-speed freewheels, if you cannot accurately shift to the intended gear or if gear changes are not

By the way, SUMLON has been manufacturing bicycle parts for over 15 years. Contact us if you are looking for a bike parts factory or a one-stop wholesaler. Peace